Project XP-836 "F" Car- Development to Production

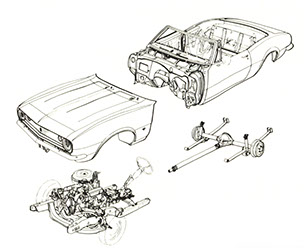

Green lighted for development in August of 1964, Project XP-836 F-Car was developed as a dual purpose platform. Its first and primary objective was to be a direct market competitor to the Ford Mustang. The second purpose was to create the engineering underpinnings and design basis for the 1968 restyle of the X-Car Chevy II Nova. To this end, the incorporation of a subframe was a critical change in conjunction with the utilization of a unibody design concept.

The basis for the initial styling was brought to life by the addition of XP-836/F design features on the then current production 1964 era X cars to evaluate the function and operability of the projected styling; these were the early prototype XP-836/F sheet metal equipped Chevy II based "development mules".

<

>

"Crash" is the term that best defined the speed in which GM proceeded with development. Through the combined efforts of Chevrolet and Fisher Body Engineers, all Sheet metal styling was already close to final by December 1964. The Chevy II test mules were critical in this role as the new prototype XP- 836/F panels were quickly grafted, removed and reinstalled on the mules to check the design, fit, finish and aesthetics. Next to take form was the general look and design of the bumpers, grills and the lamps. The interior portions of the design included testing the real function and ease of access to the instrument panel and the exterior ornamentation on the body. Remarkably, all was completed by the end of September 1965.

Fisher Body completed the Sheet metal tooling in November 1965, completing the first Operations Description Manual (ODM). Paving the way for the physical fabrication of XP-836/F Prototype #1 (a non car), which was completed at the Design Engineering Center (DEC) in Flint Michigan in December 1965. Prototype #1 was completely hand built to finalize the overall design and the initial engineering

drawings for development of the initial first draft of the Chevrolet Assembly Information Manual (AIM). This Car was referred to as "A Prototype That Will Not Run", because it didn't have the structural integrity to carry the weight of the sum of its parts.

<

>

Parts vendor selection followed quickly and by February 1966, contracts and specifications were ready for internal and external vendor supplied component delivery. These submissions were considered "preliminary" and were used for the next hand built prototype car #2 (another non-car) which was completed in early May 1966, again at DEC in Flint. Again, this car was referred to as "A Prototype That Will Not Run". This is because this portion of the Design Study was still in the modeling phases that included

clay, balsa wood, and primitive fiber glass for easy shaping.

<

>

Next was Pilot Prototype assembly, where the first XP-836 units would be built in an operational assembly format to test the new XP-836/F design against the function of a mass production assembly line. Additionally, these Pilot Prototypes would be referred to as "Prototypes That Do Run" by General Motors Executive Bob Lund. They would be the first working prototypes and fourteen of them would be utilized at the Milford Proving Grounds for engineering testing. Pilot Prototype Assembly would insure compatibility with the demands of mass production on both the design of the new vehicle, as well as, the machinery the vehicle would be made with.

The “then” modern GM Norwood, Ohio Assembly plant was selected for the (F)-Pilot Prototype assembly. Production readiness for the (F-Car) at the Norwood Plant was ongoing there as early as 1964, with the removal of the truck production lines on the Chassis side, as the plant was made ready for the receipt of the new car line. In the case of the XP-836/ F-Car... initially the name "Panther" was floated within the press and internal GM sources in Detroit, but officials were evasive in not specifically selecting a formal name for the car.

<

>

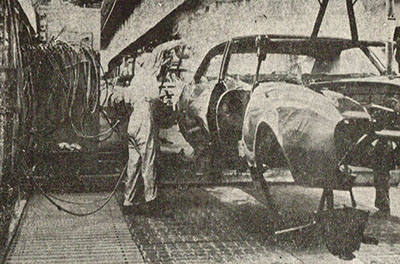

The selection of Norwood for the all new "Panther" XP-836/ F-Car was not a random act, as GM as a corporate policy had embraced the use of robots for all future GM assembly line production and with XP-836…. Norwood was selected to be the very first GM assembly plant to install and incorporate robotics for automobile assembly. GM Robots were viewed as having the efficiency to further increase line speed and bring weld consistency critical for the new unibody structural feature, which in theory, would allow for an increased unit production rate along with better structural quality. Traditional manual spot welding had drawbacks and often produced inconsistent results and structural binding inconsistencies.

Like Non-Working Prototypes, which first proved the idea and established a physical example to work from, Pilot Prototype production cars established a physical example in a mass production environment and differed from a prototype…. as they were real automobiles upon completion. Work began on the first "F" Pilot Prototype at Norwood on May 17th, 1966 at Norwood Fisher Body with the first car built, a bare bones gold/gold 6 cylinder coupe with "show paint required". This car was specified for Chevrolet final assembly as equipped with a 3 speed transmission and 110V wiring for plug-in static display usage by Chevrolet for large venue displays. This particular car is know as "The Detroit Sales Convention Unveil Car", N100001.

This car would be shipped first to Detroit and then later to Yukon, Oklahoma. Later in life this car would wind up in private hands and become a race car before it was located in 2009 and restored by Pilot Car Registry. This particular car is the first production

"F" car assembled by General Motors Corporation as an automobile.

By mid June 1966, Norwood had already completed basic assembly on most of the Pilot Prototypes. The Pilot Prototypes were hand built initially in the rear area of the plant under extreme secrecy. The first builds had lots of engineering changes due to fit and alignment issues and a team of engineers were assigned to make the corrections and get the engineering revisions back to Detroit right away for approval. Said an eyewitness to the build, "designs that work in a hand build environment do not always transfer well to a mass assembly environment…. I mean the basic design will almost always function, but changes were needed to adapt the design to the designated assembly method, which

required an extra hole punched here or there-these were all design changes".

<

>

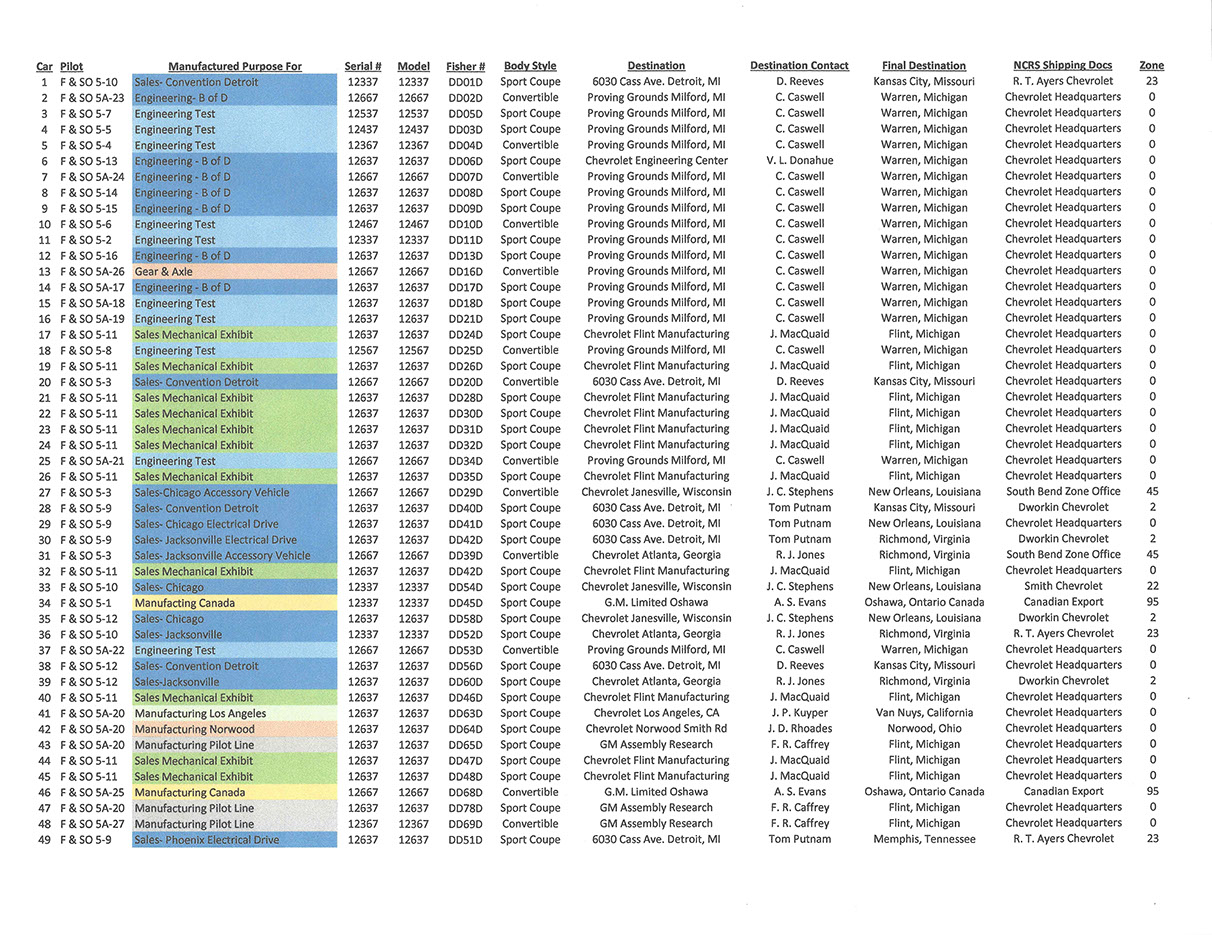

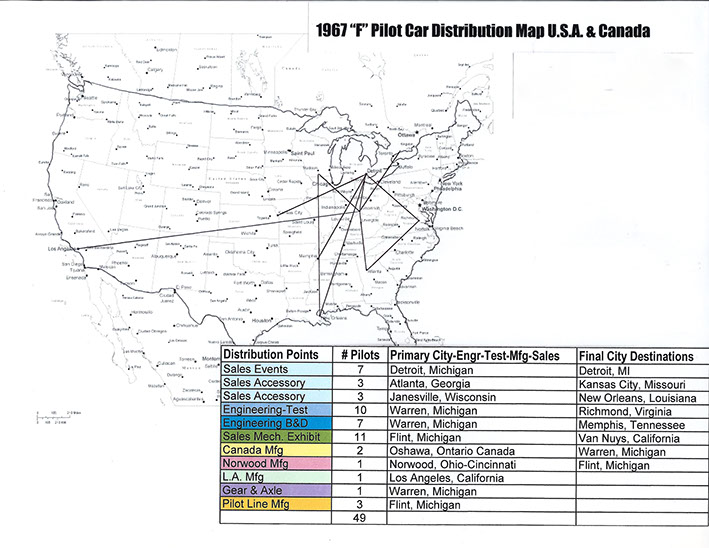

Said one engineer, "this was super-secret work…. we did not even know the name yet and the first "F" Pilot Prototypes were built and shipped before emblems were even ready for the cars, so we did not even know where to punch the emblem holes in any of the sheet metal". "We were working closely with F.A. Braulieu and we had Jim Seim up at the pilot line specifications section in Flint…. where they had been working with cobbled up Novas checking the driveline parts for the new car. Norwood was scheduled to make 49 cars-49 Pilot Prototypes- that is how much we were trusted in those days, that was a really a big deal". Indeed, the combined Fisher Body/Chevrolet Norwood plant was scheduled for 49 "F" Pilot Prototypes and General Motors Assembly Plant (GMAD) Van Nuys was scheduled for 3 "F" Pilot Prototypes.

<

>

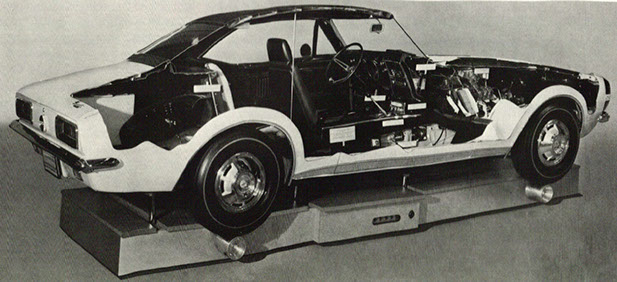

The engineer went on: "The car I recall the most was this loaded yellow 350 car that we did for the guys up at sales- It was supposed to be an SS but we did not have the emblems yet...you know they cut that damn car in half and they laughed about it...what a waste".

This particular car is know as "The Cut-Away Car", N100017.

Pilot Line ramp up to production was not just a Norwood affair. All of the allied suppliers from the nearby Ohio Based Fisher Body Hamilton stamping plant, to Harrison Radiator up in New York state- all had engineers on standby to integrate the "F" car's various

component parts into full production.

Tooling changes, die corrections, print revisions and subcontract supplier modifications were all part and parcel of bringing a brand new car to production. For GMAD Van Nuys, being tasked with building 3 "F" Pilot Prototypes meant relying on Norwood to sort

out most of the assembly detail.

As to the name of the "F-Car"…. On June 29, 1966, all doubt was removed by none other than Pete Estes. In a dramatic 10:00 am, 14 city network news conference, Estes dropped the bomb... "It's the Camaro". Estes went on to explain that both the Norwood Plant and the Van Nuys plant would assemble the new model with scheduled production set at 1250 cars each day. Estes then turned attention back to the Camaro, stating that the new car would have a full line of safety equipment and that Camaro alone was estimated to account for 12% of Chevrolet production in 1967. When asked by a reporter how Estes came up with the name "Camaro", Estes remarked that "he went to a closet and came out with the name". Other early names considered for the "F" were the "GeMini", "Panther", "Commander" and “Wildcat”. GM had spent in excess of $100,000.00 in tooling costs for the potential name plates and in the end, paid for one final tooling design for "Camaro".

<

>

During the Spring and Summer of 1966, the Pilot Prototypes at Norwood were initially built…. then hidden and then taken apart and reassembled over and over again in a nondescript brick building next to the Chevrolet Chassis side. This took place through the remainder of June and July in order to make the final revisions to the Fisher Body ODM and the Chevrolet AIM. This process was instrumental in capturing the assembly level procedures, tooling changes, assembly techniques and assembly time studies for Regular Production Option (RPO) content. This was critical for the flow down to the vendor for design modifications, as well as, component assembly parts.

With the plant fences covered in blacked-out camouflage, the first day of regular Camaro production at Norwood was Sunday August 7th, 1966. Production at GMAD Van Nuys would follow. The completed Norwood Pilot Prototype Camaro's were discretely loaded into enclosed transports and spirited off for a number of hi profile unveilings ....and so it began 50 years ago.

Pilot Prototype Distribution Spreadsheet

Click The Image To Read

All of the Vehicles produced by the former General Motors Corporation at its long expunged Norwood, Ohio factory are all existing trademarks of the new General Motors Company. Any and all historical marks as used here are used for identification, description, illustrative, and educational purposes only. This site is not affiliated with General Motors Company.

By: Logan Lawson

Registrar Of WWW.PilotCarRegistry.com

Copyright 2014 Logan Lawson. All Rights Reserved.