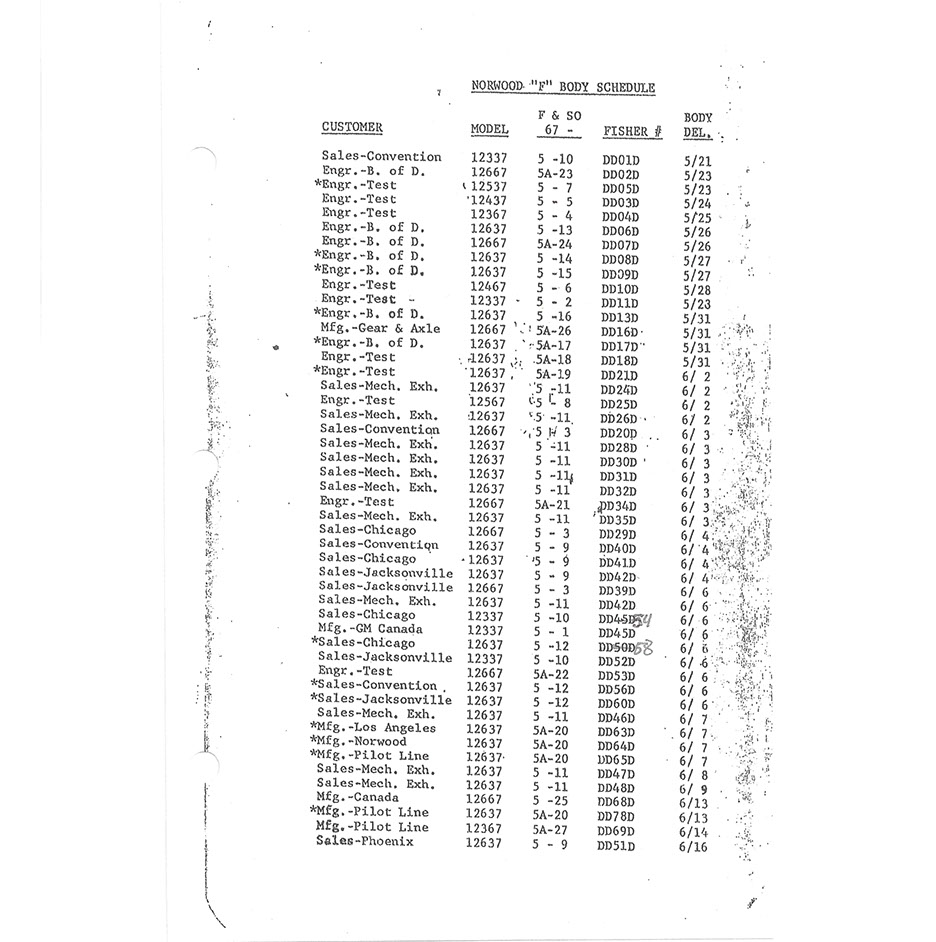

• The Majority of the copies of the Norwood Pilot book in circulation today are bound incorrectly. These copies were given to all attendees of the 2013 Norwood gathering. These copies were bound in an incorrect order by Kinko’s when Jim Seim, Pilot Program coordinator, ordered them locally. To correct this error, simply cut pages individually from binding and re-collate by Fisher Body number and Fisher Delivery Date per the index page.

Do this from type written content only….Handwritten changes are later content and have no bearing on the page order.

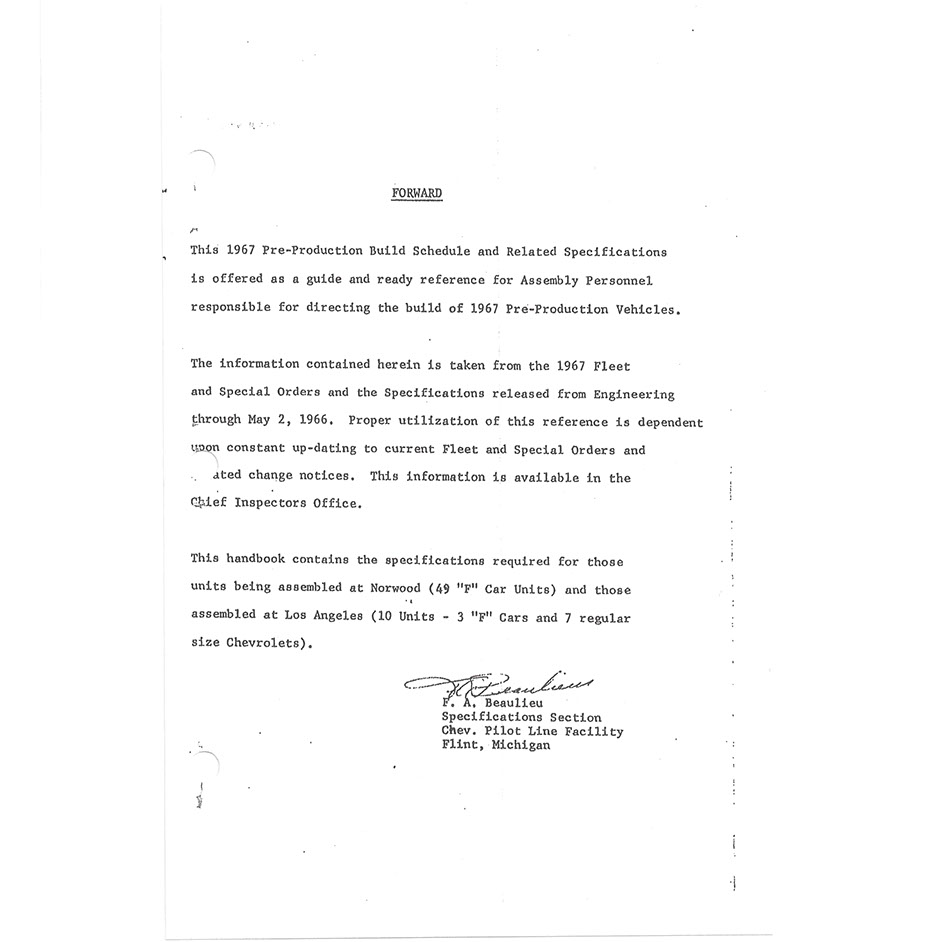

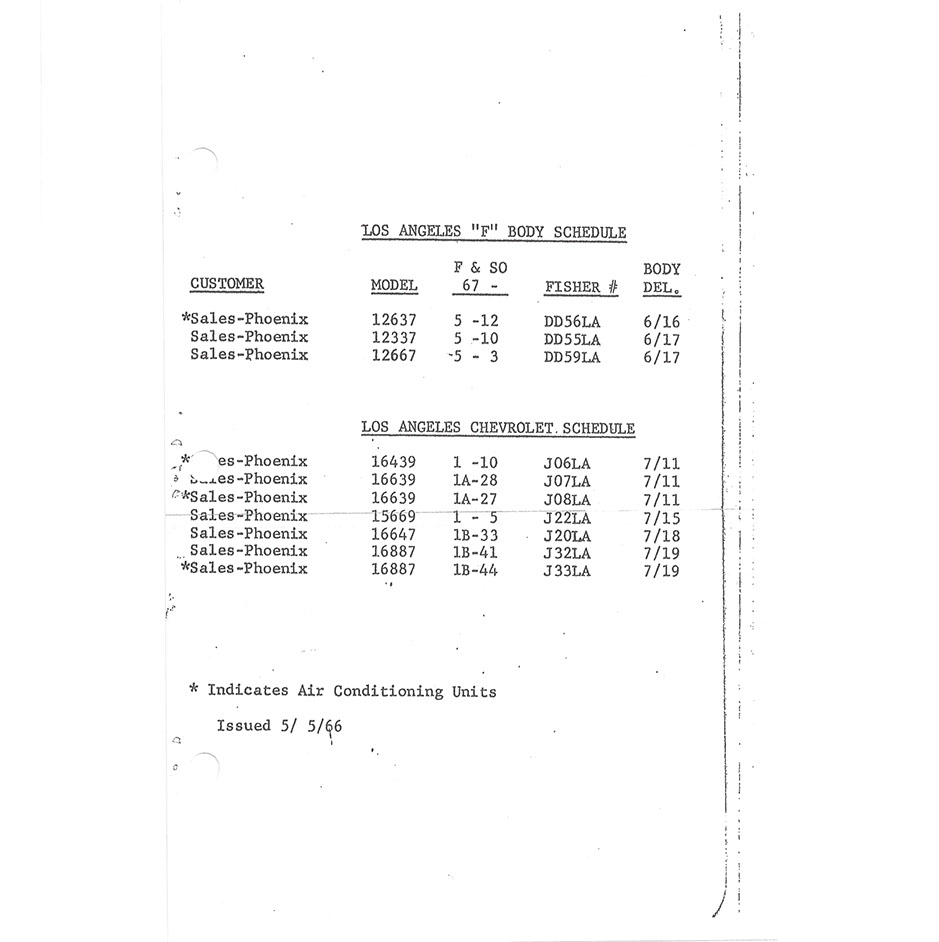

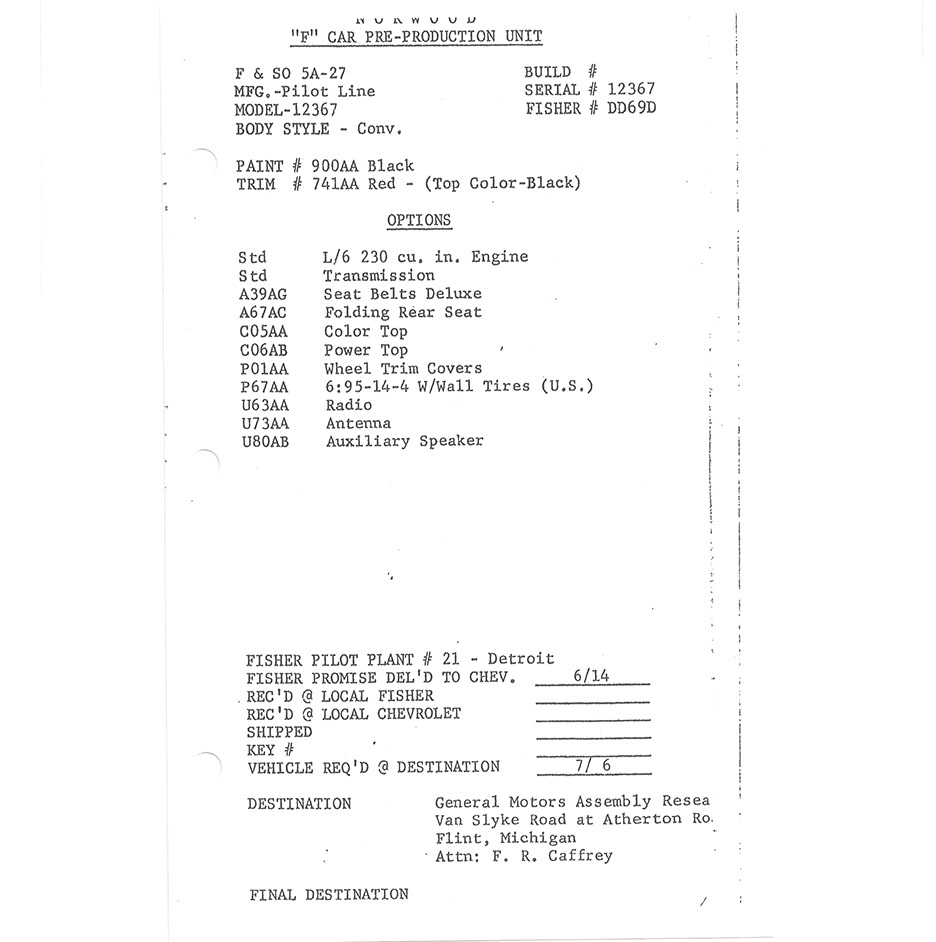

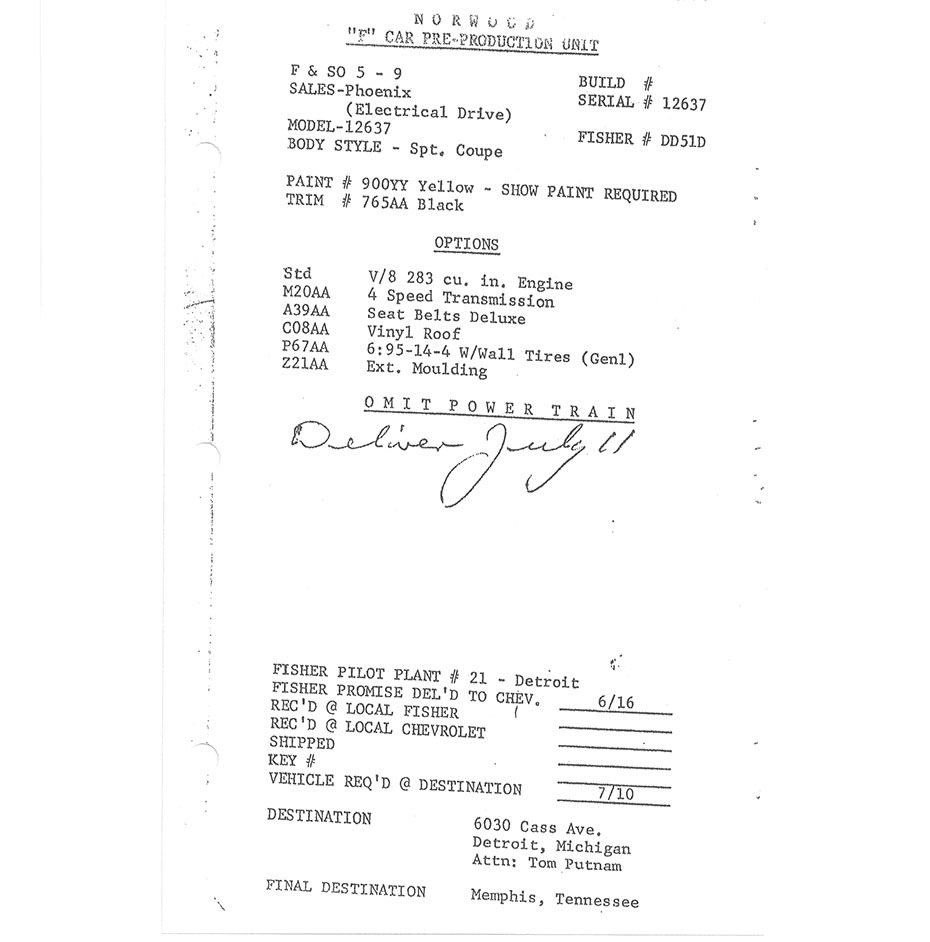

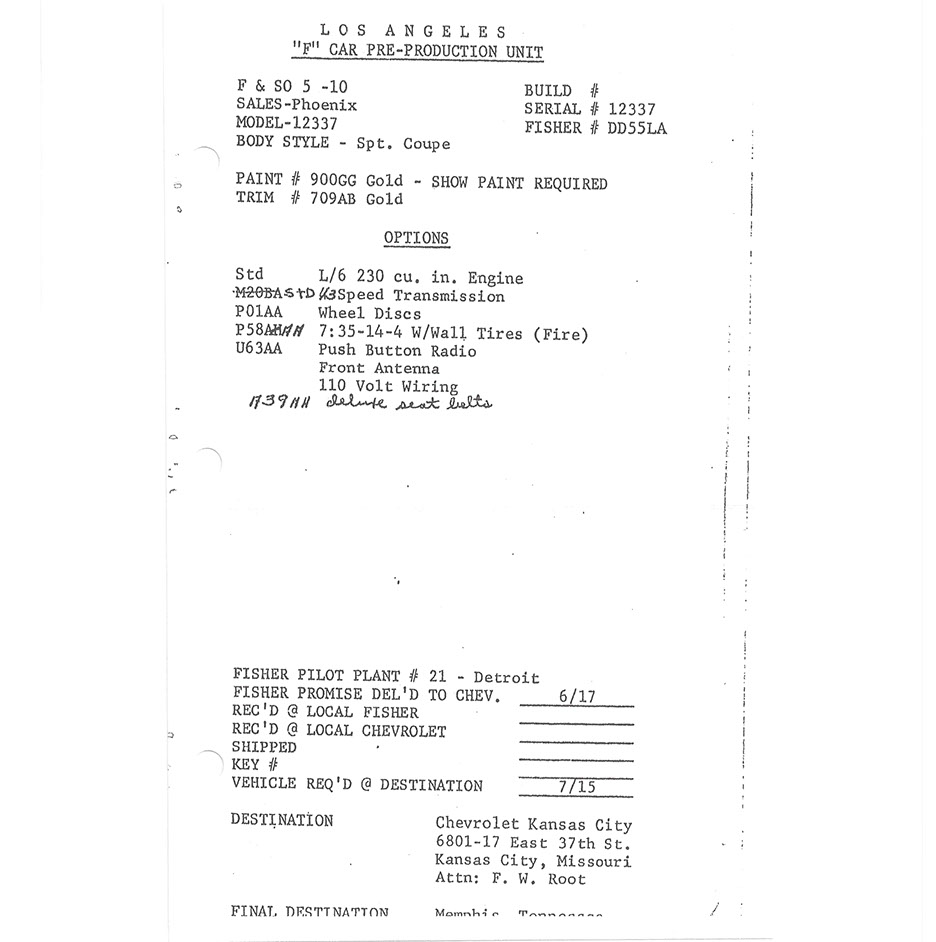

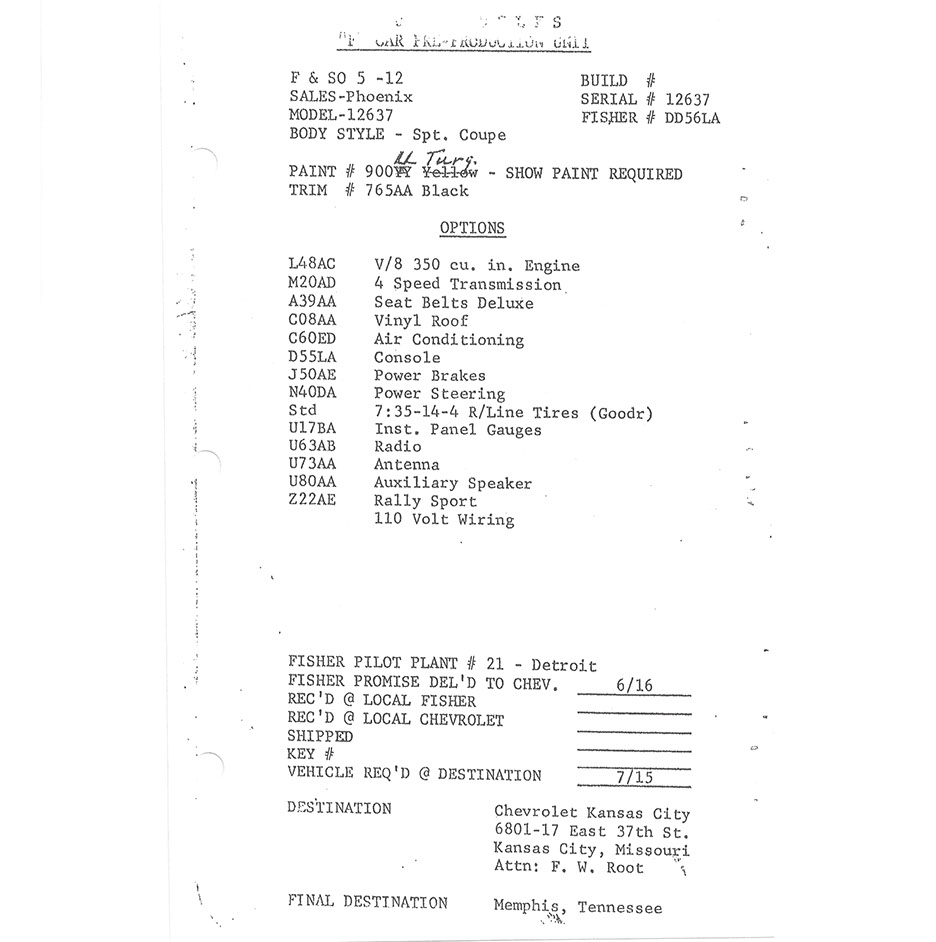

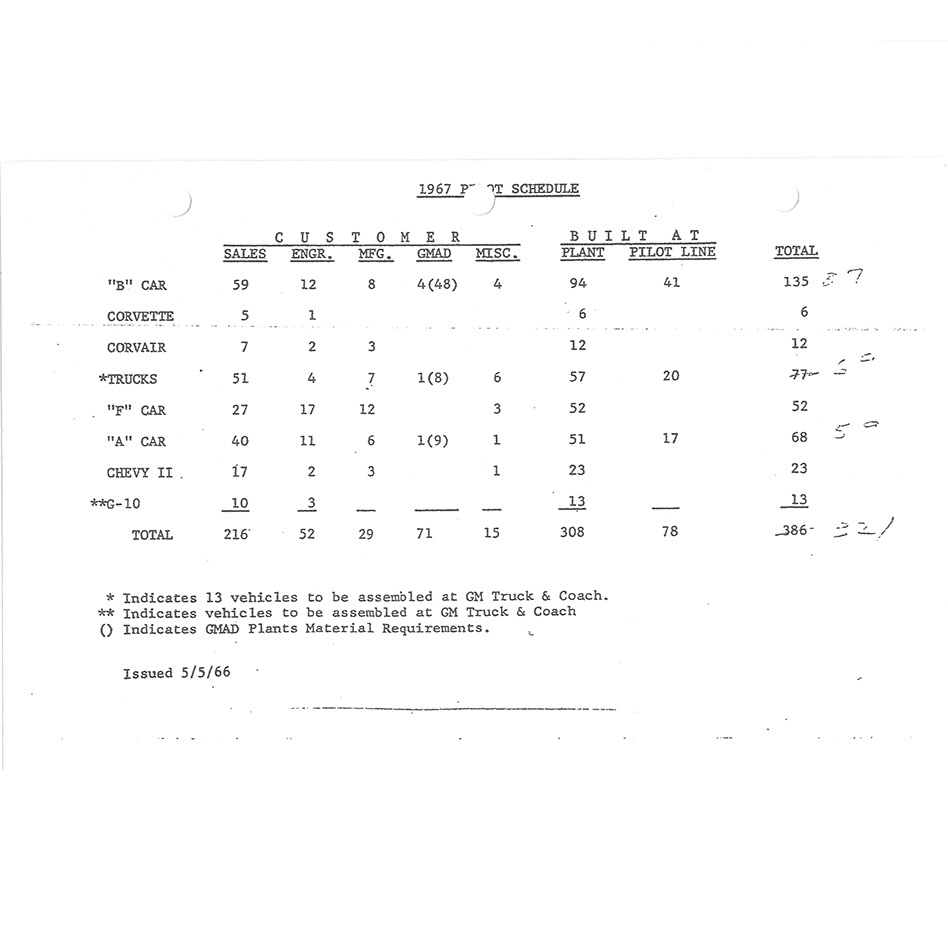

• Pilot Book was issued May 5, 1966.

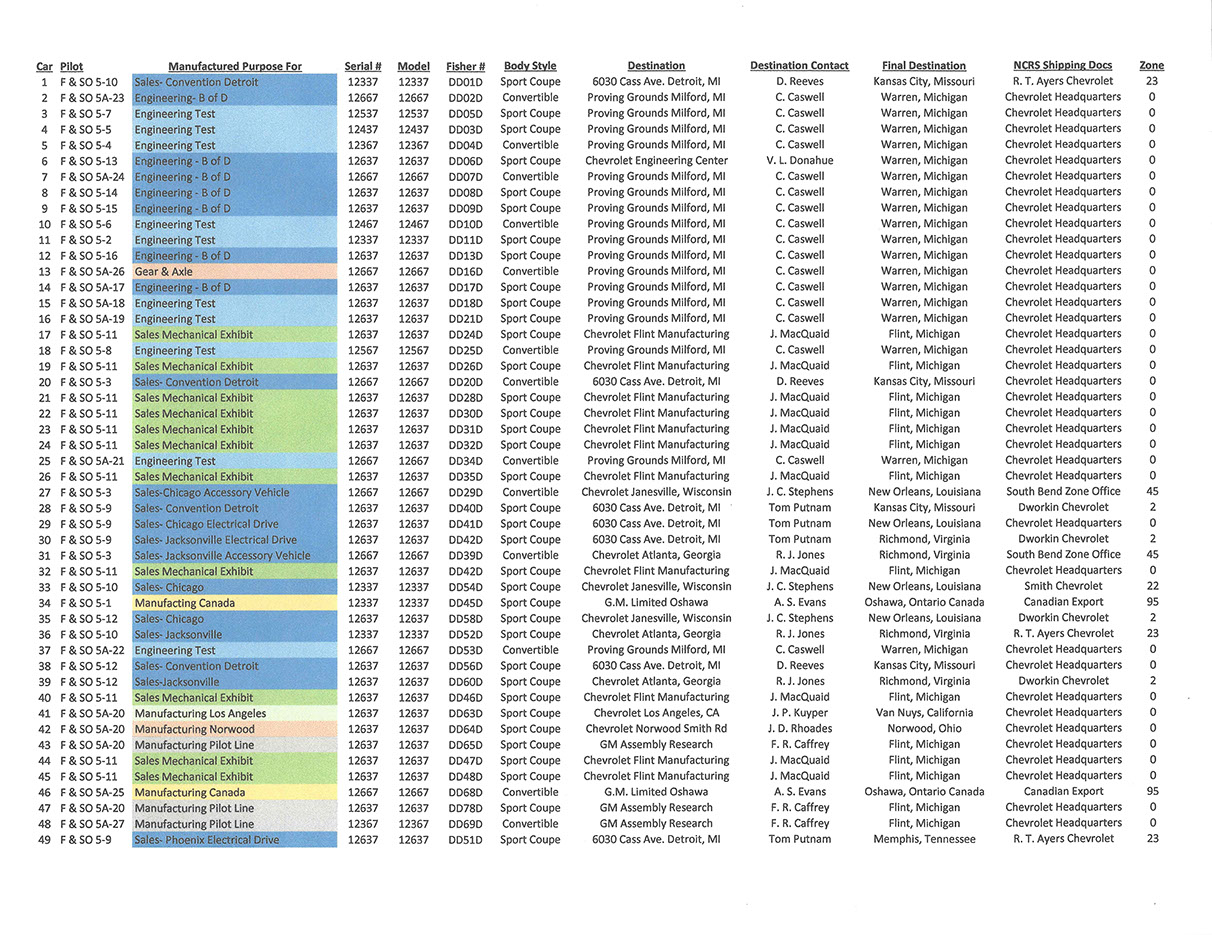

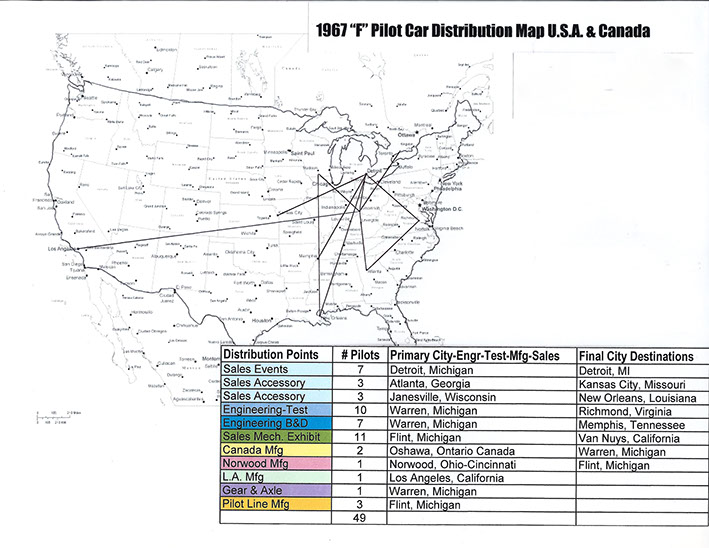

• Total Norwood Pilot Prototypes – 49

Coupes – 36

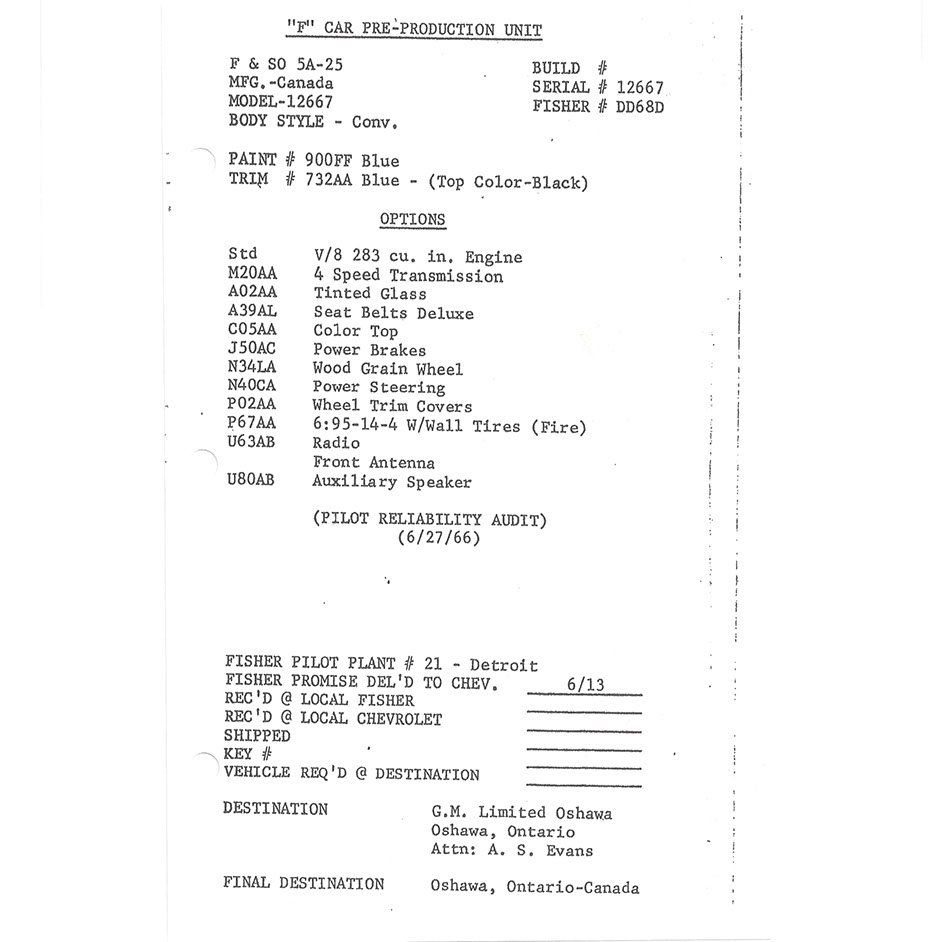

Convertibles – 13

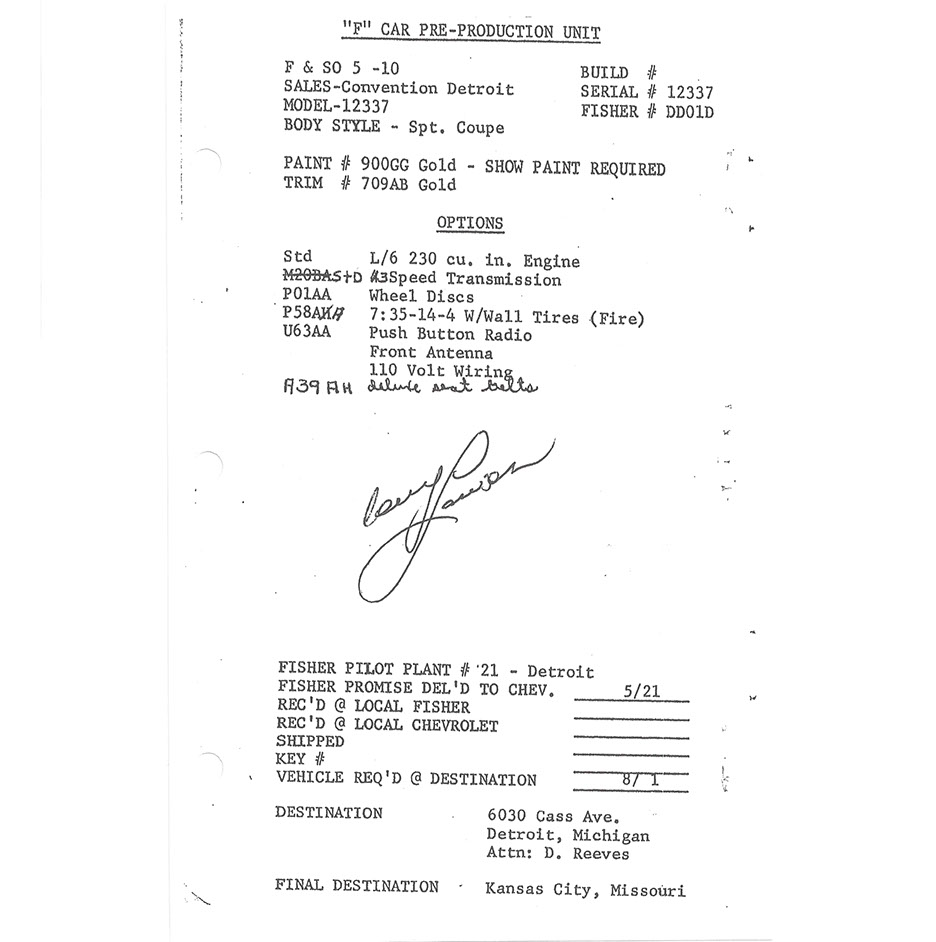

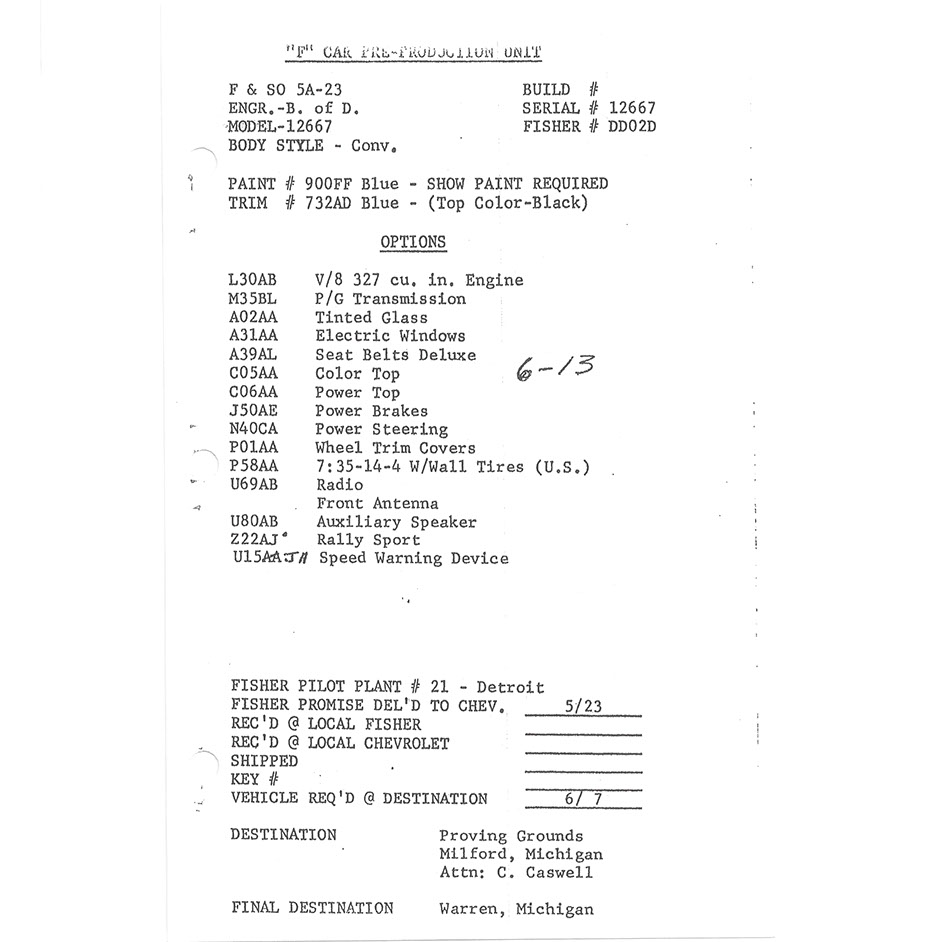

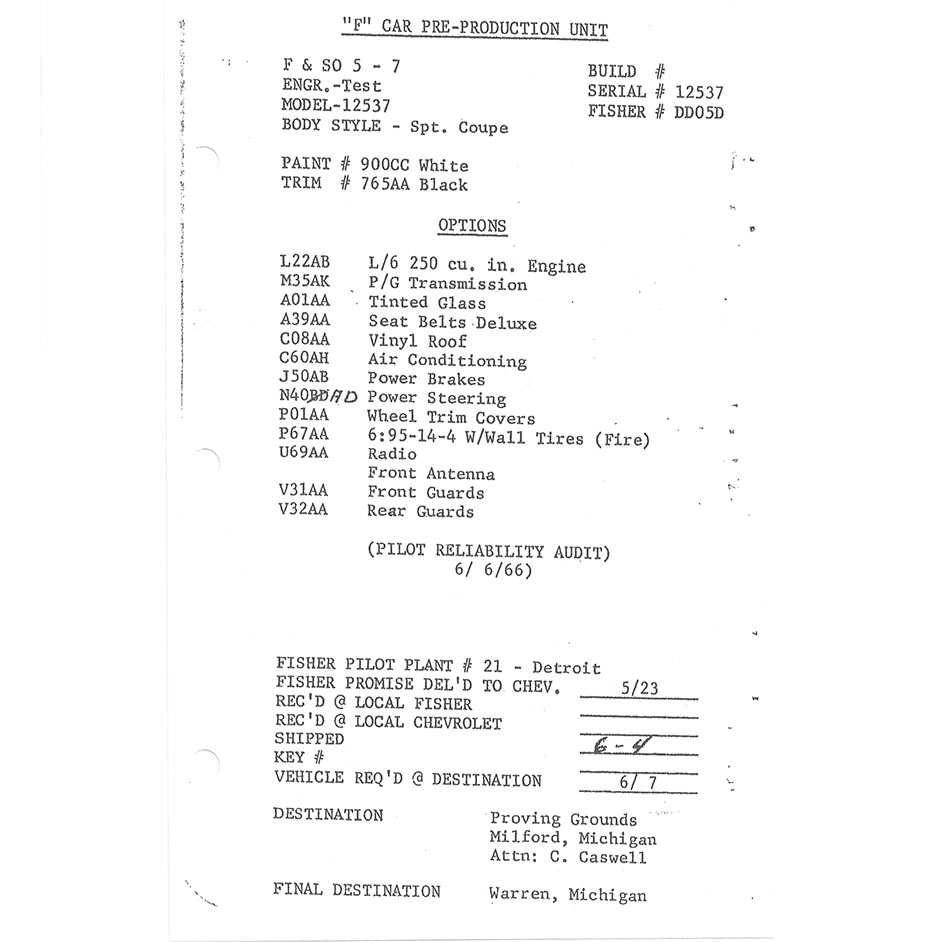

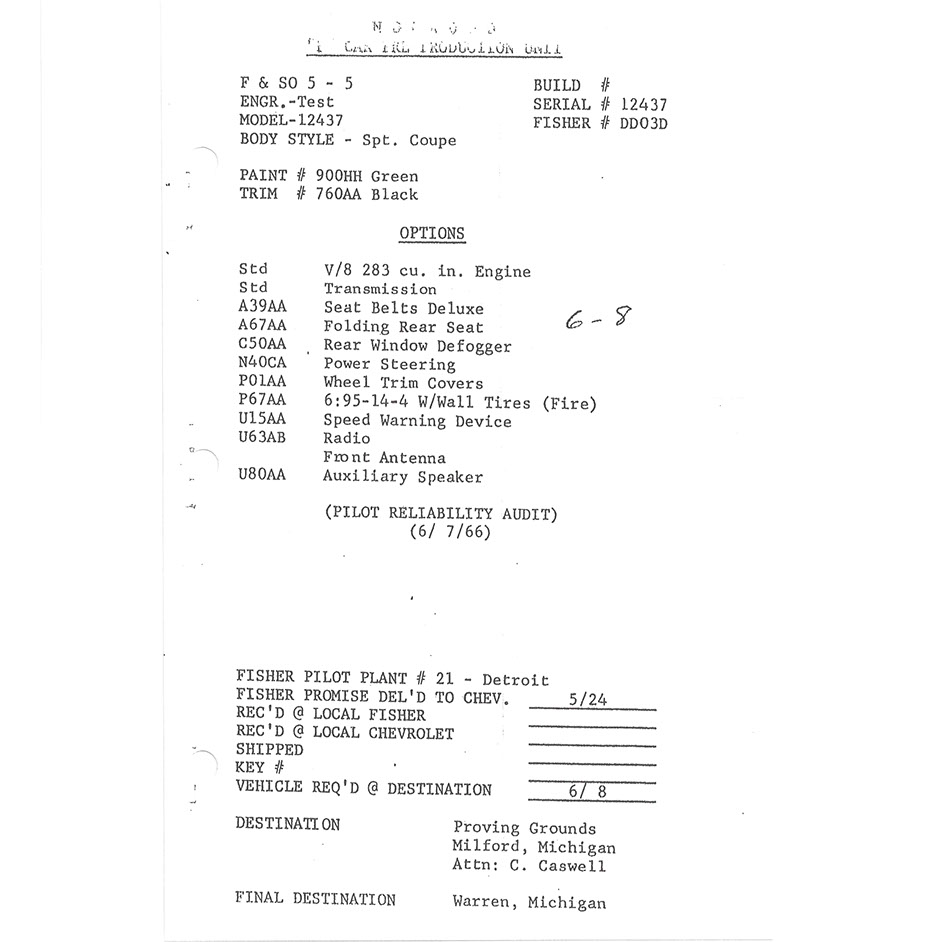

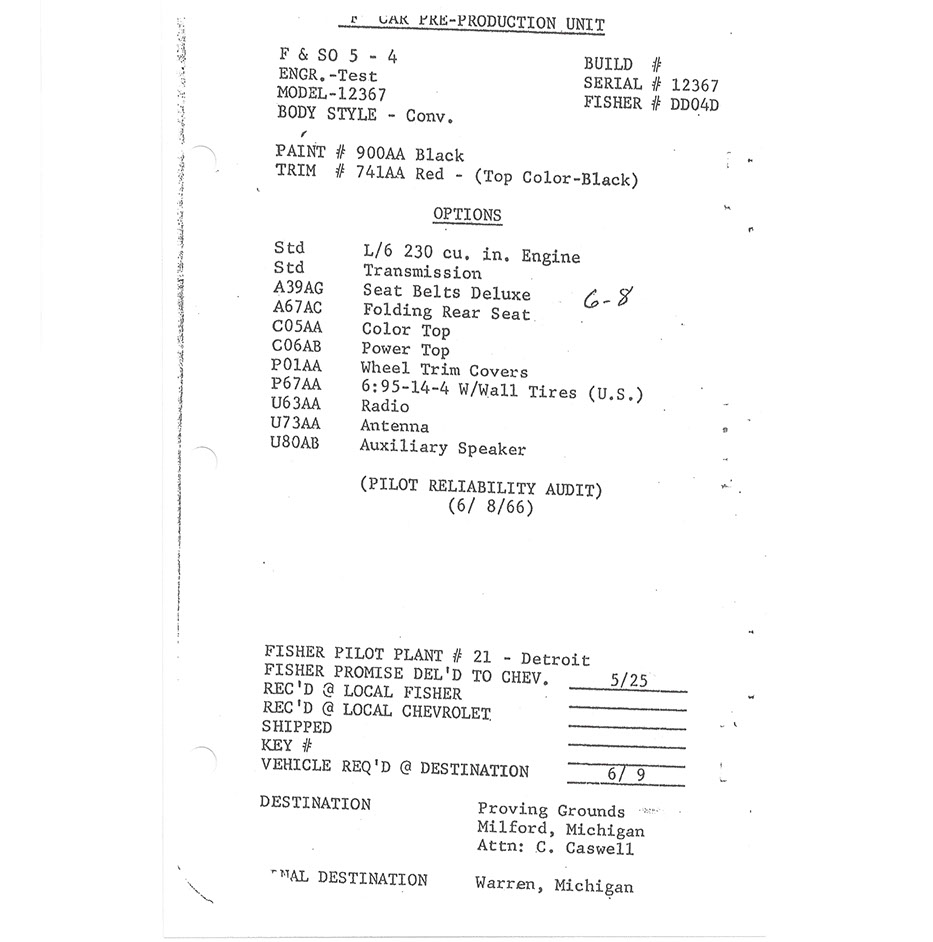

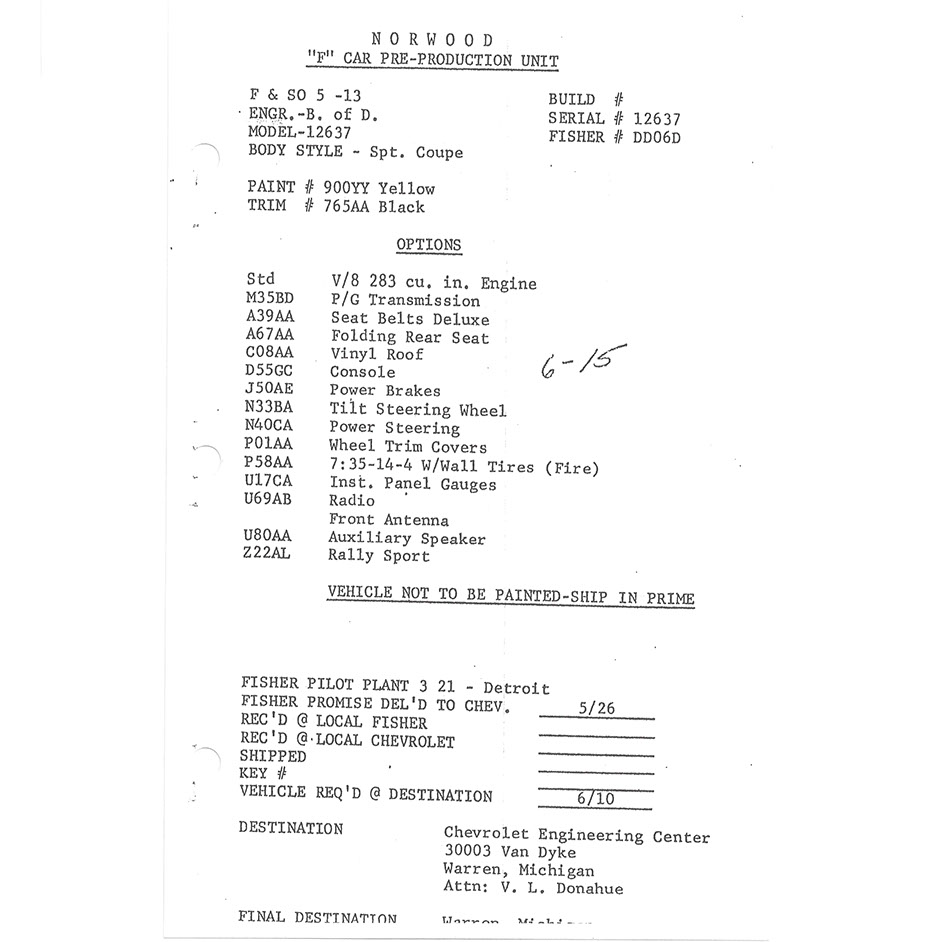

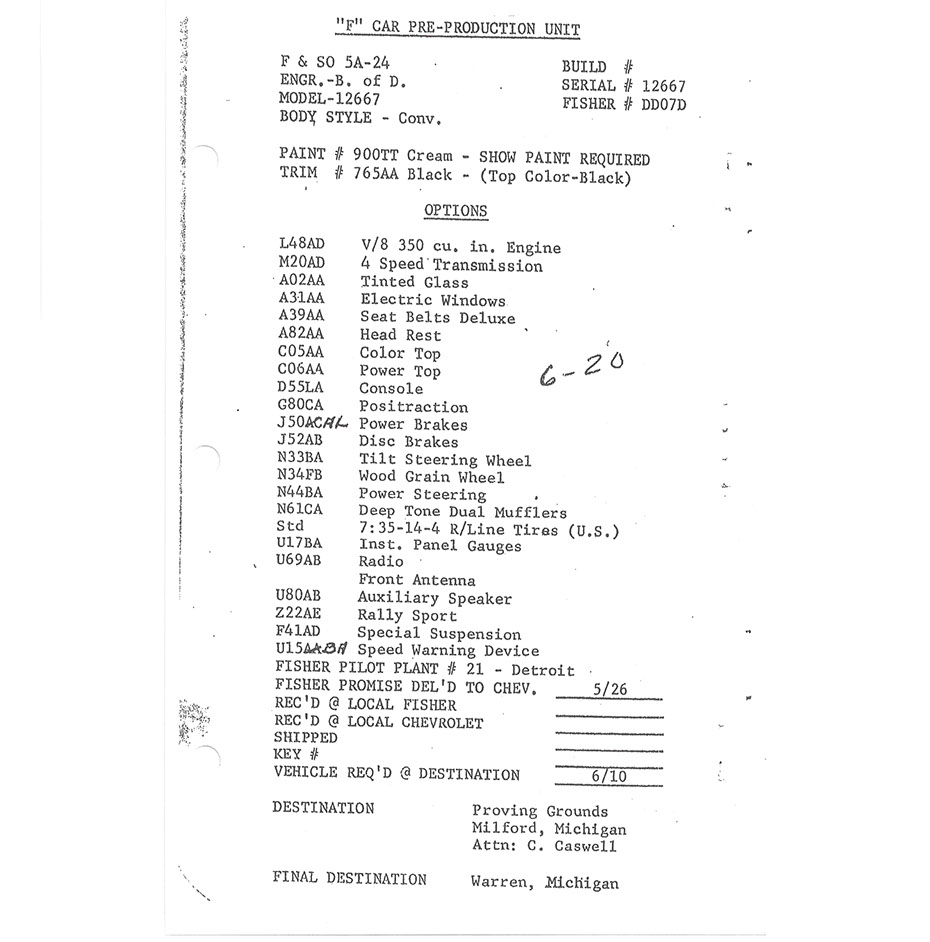

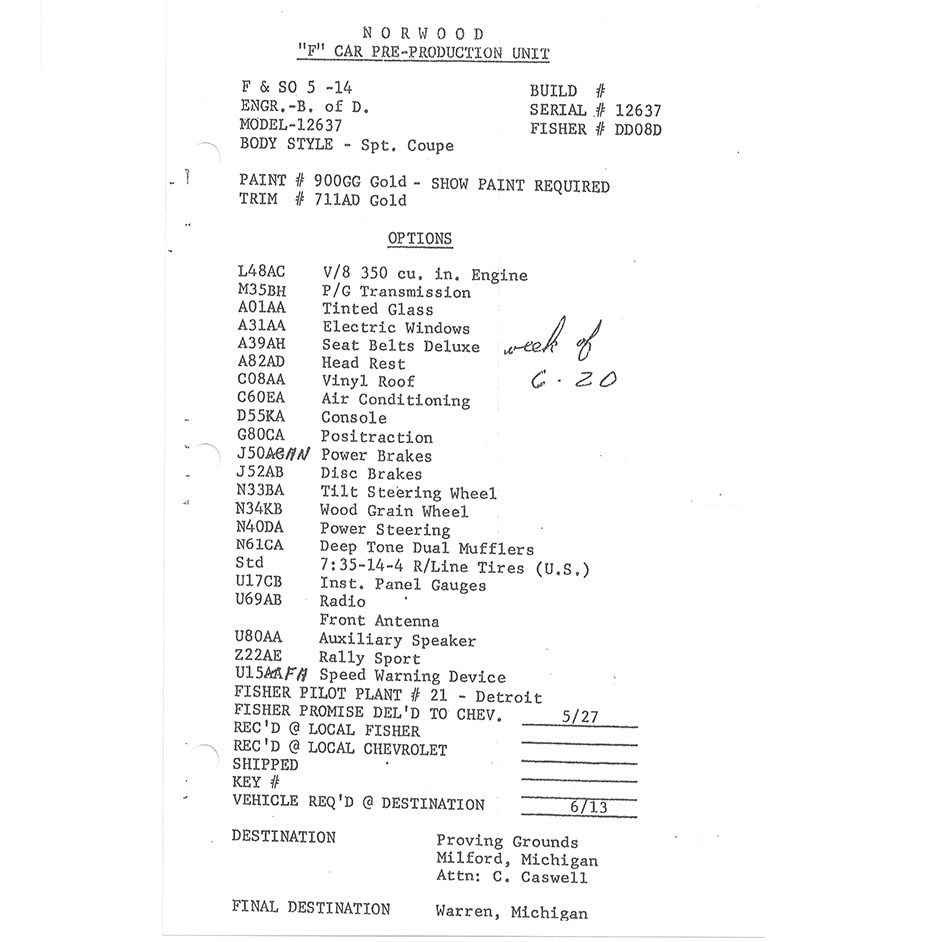

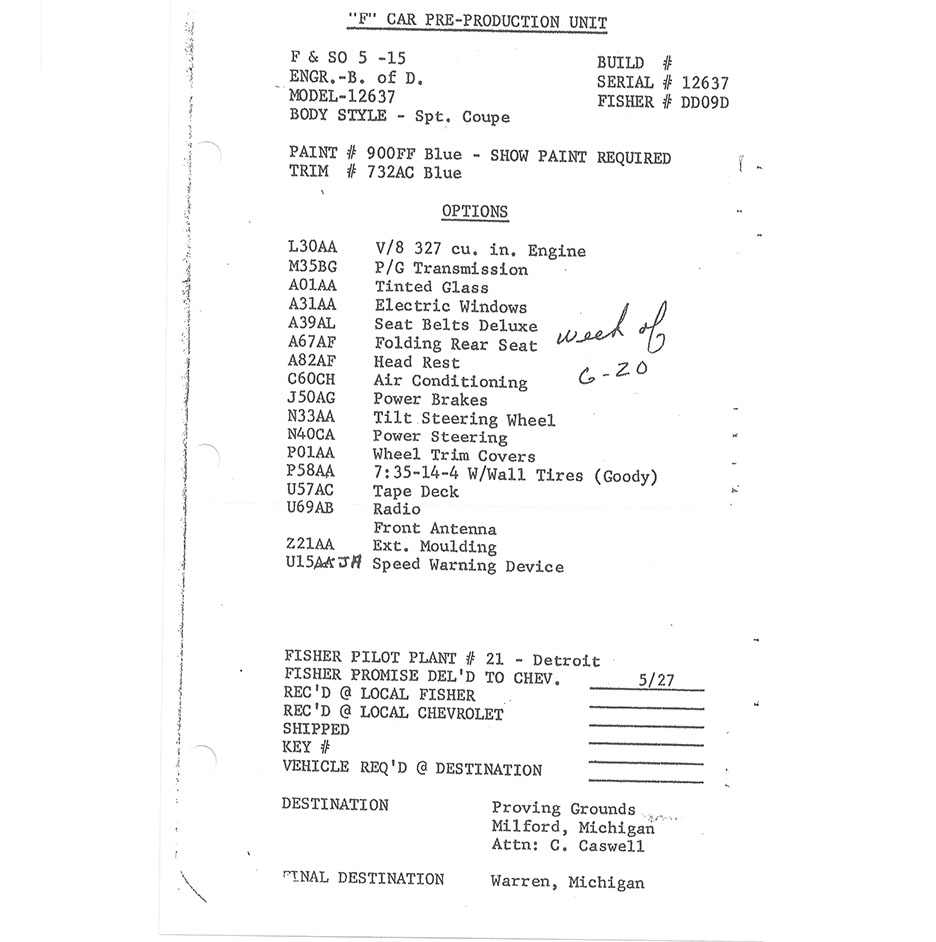

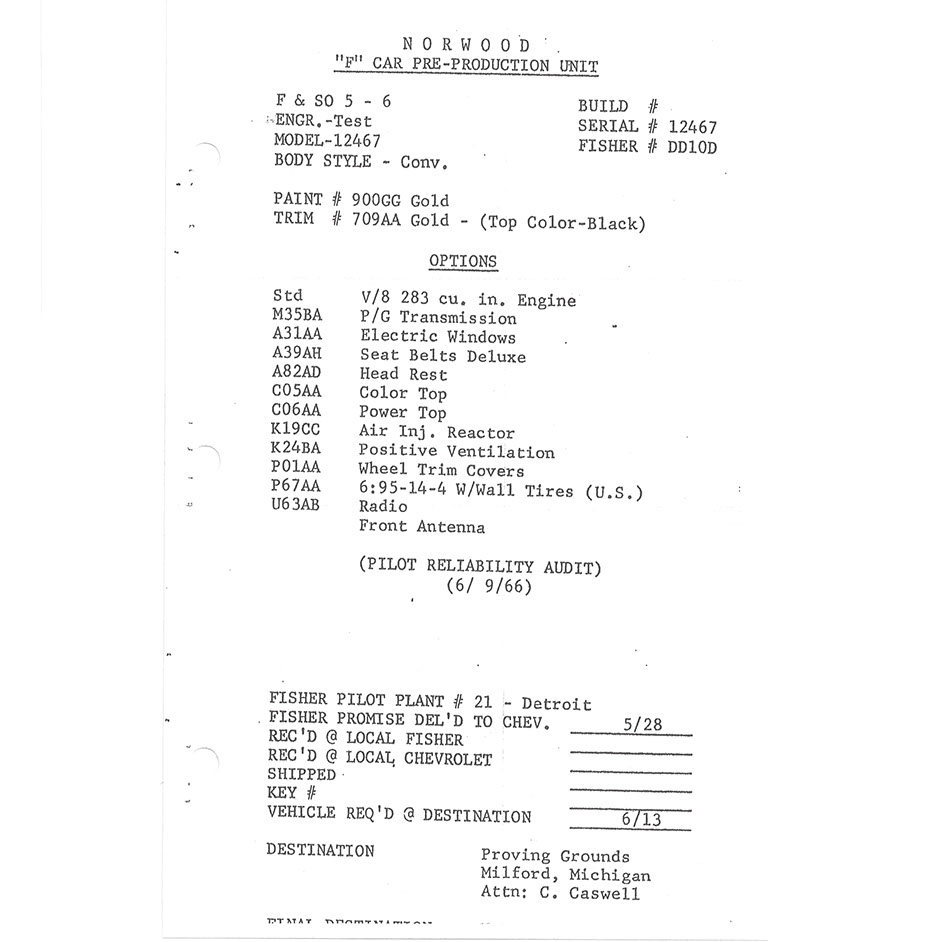

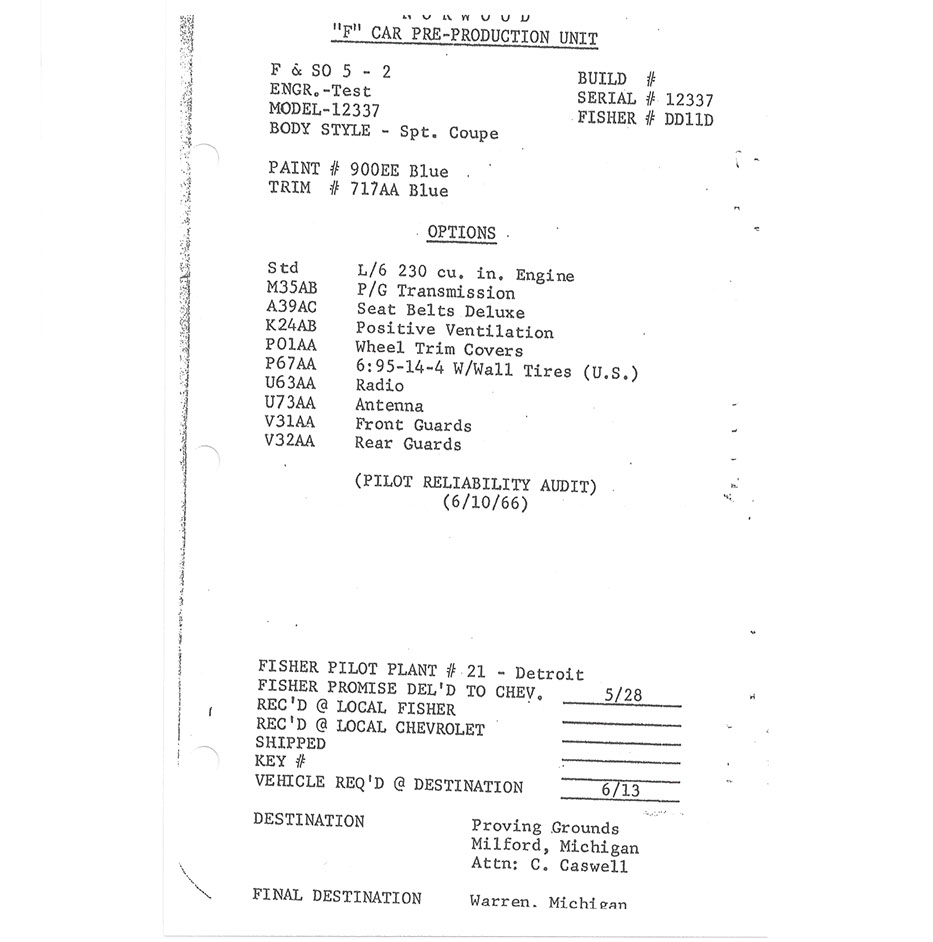

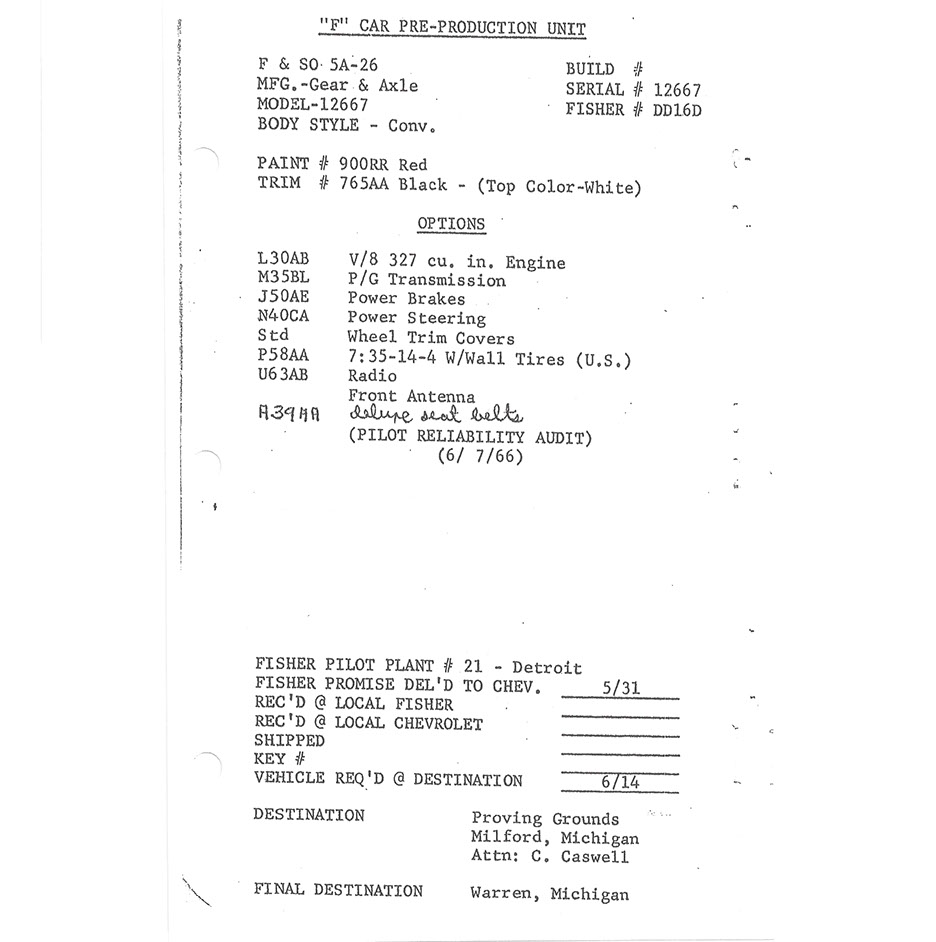

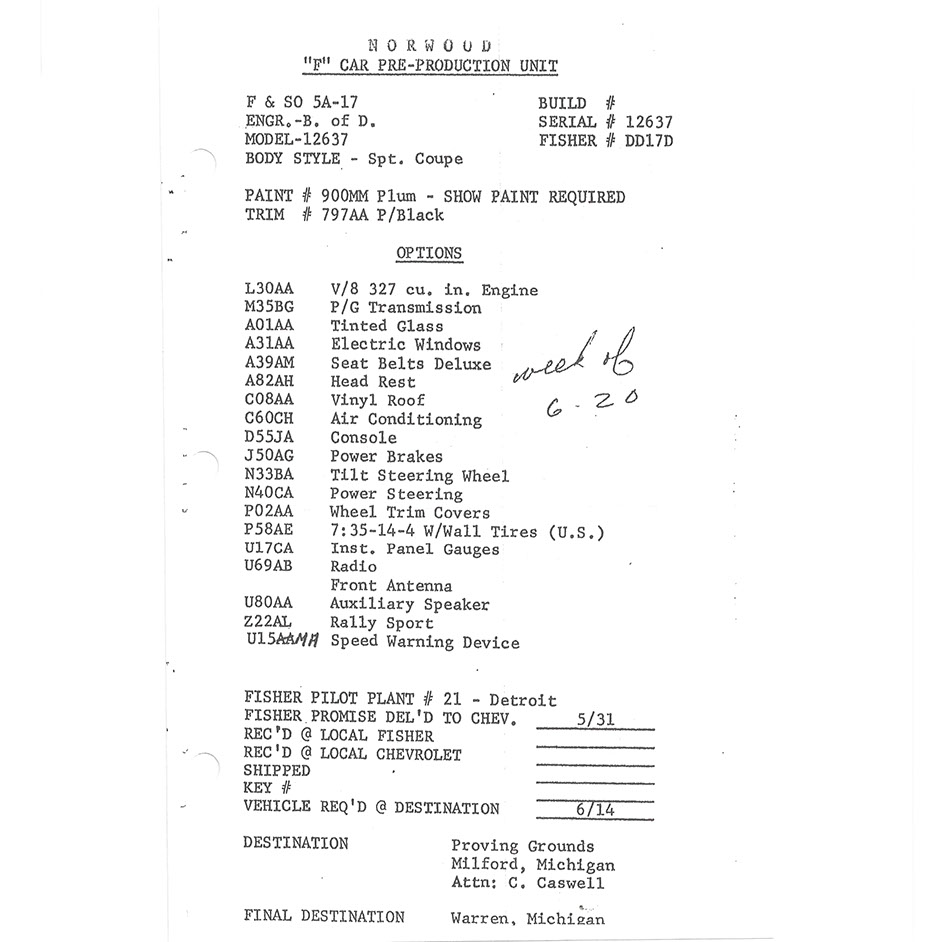

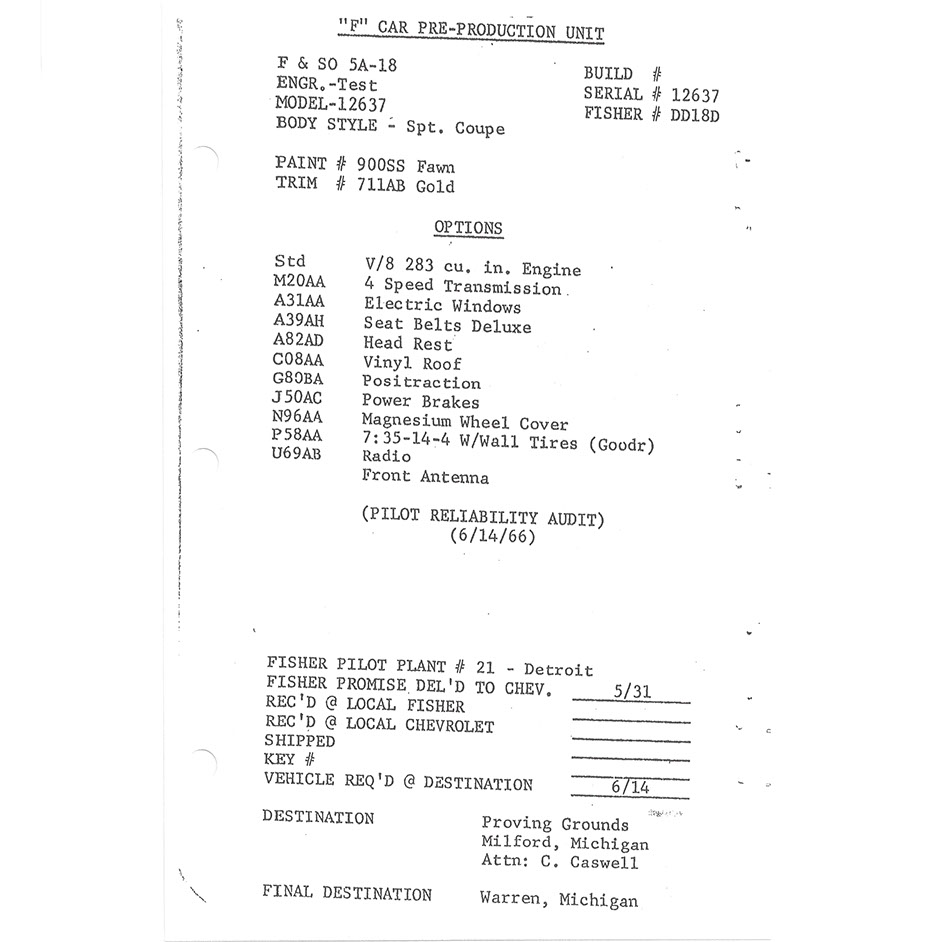

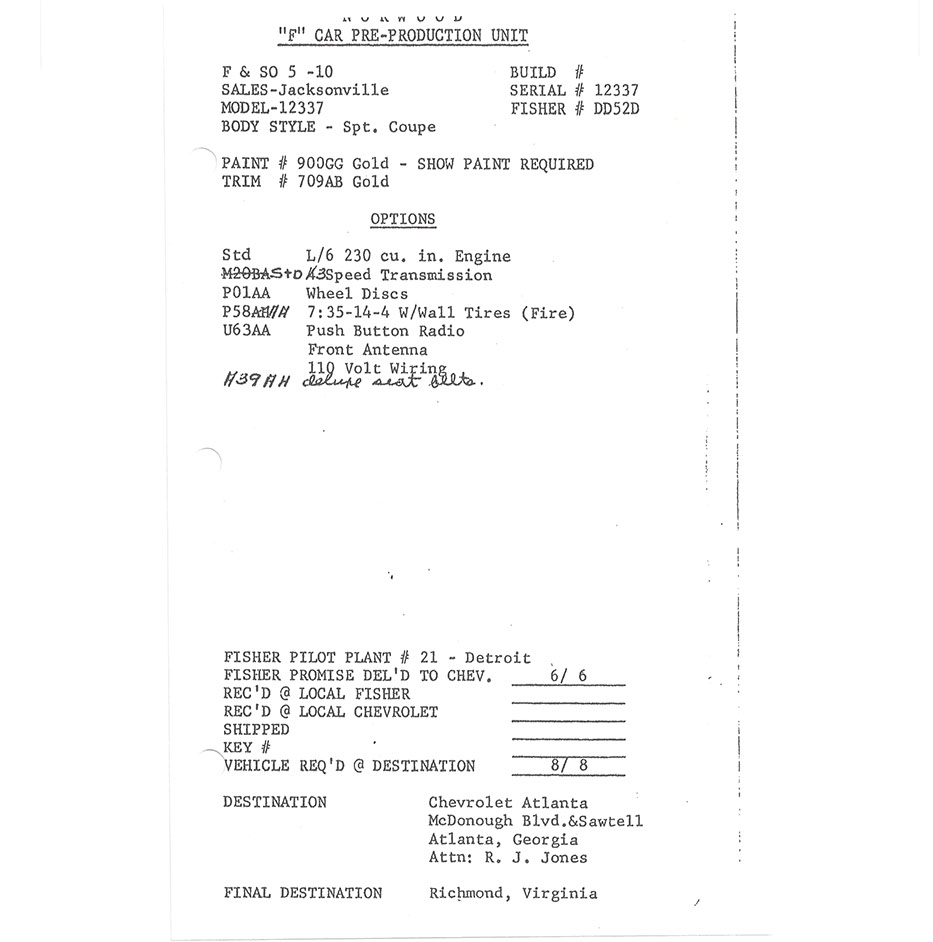

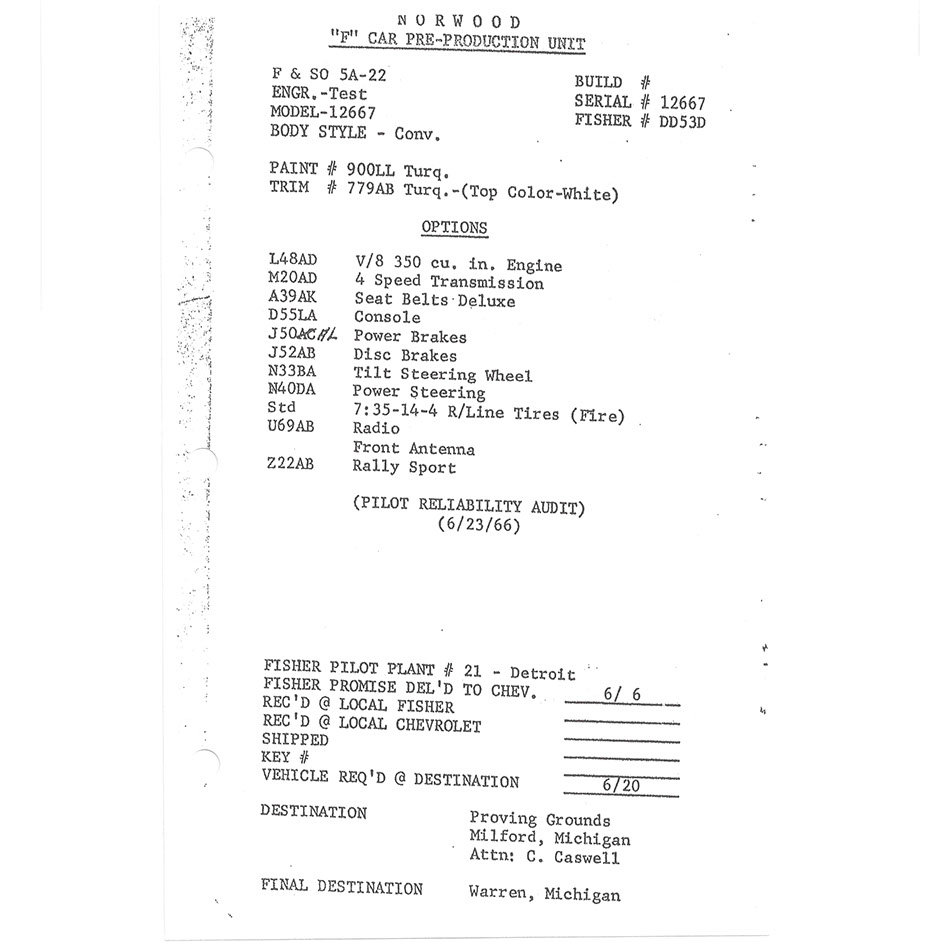

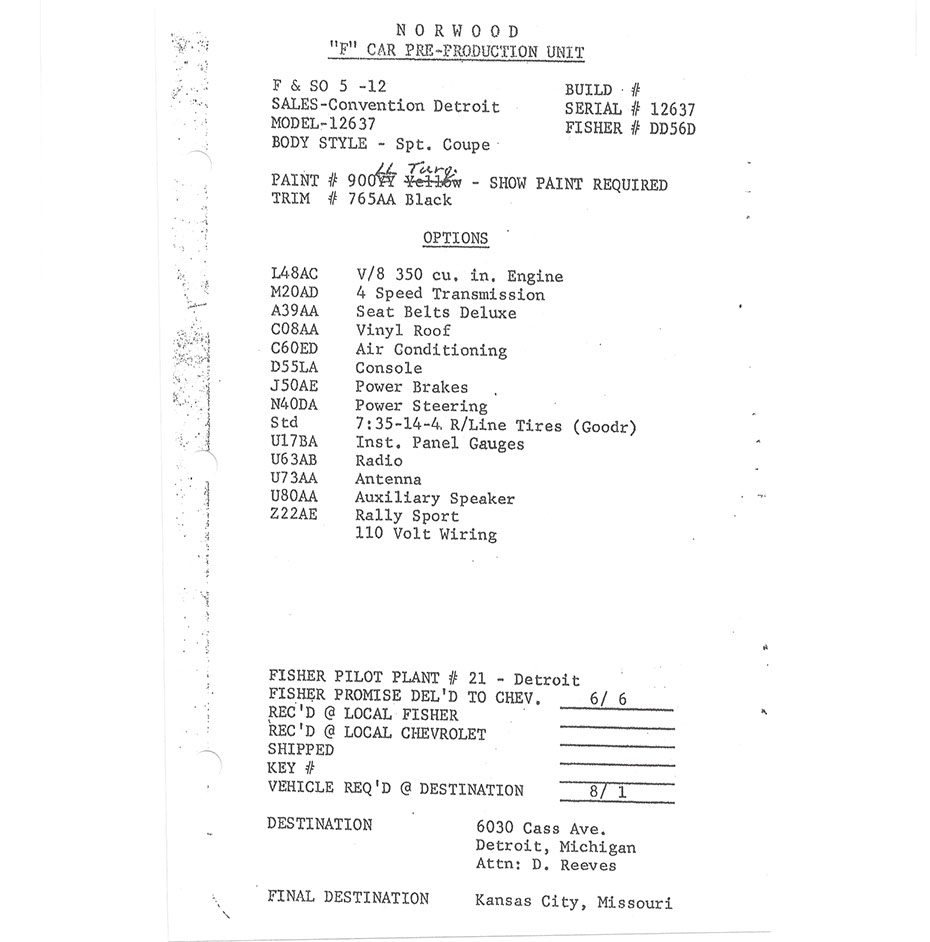

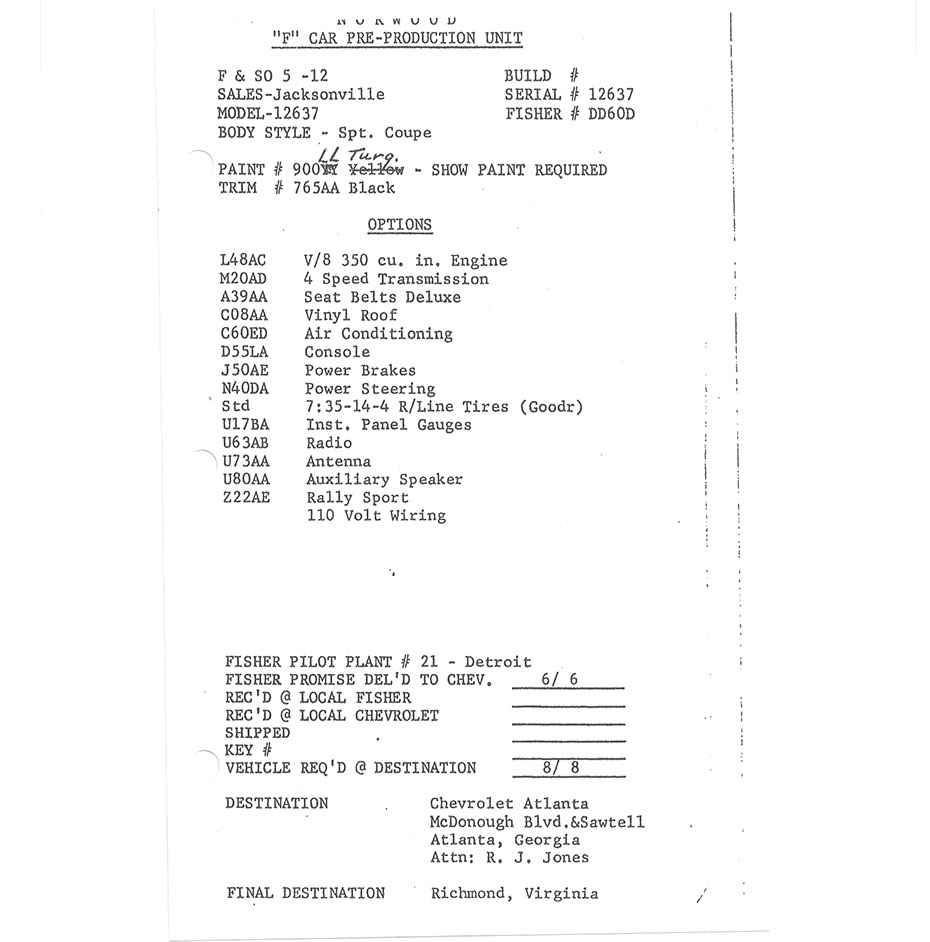

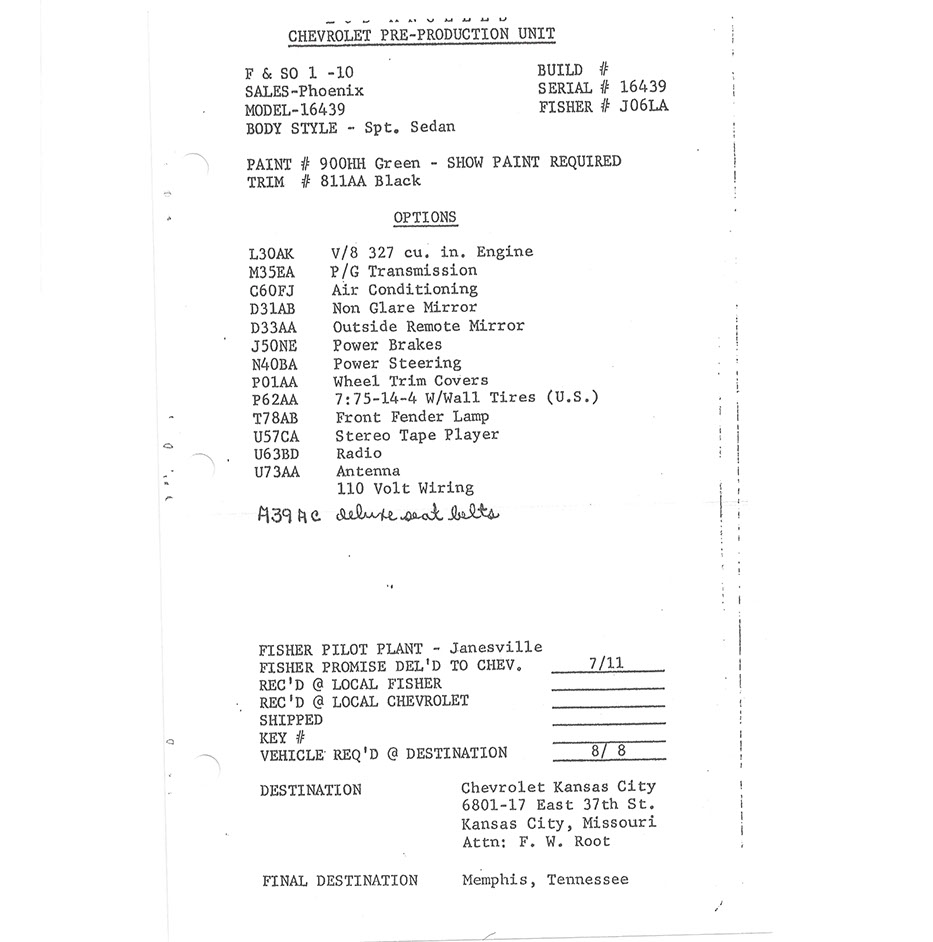

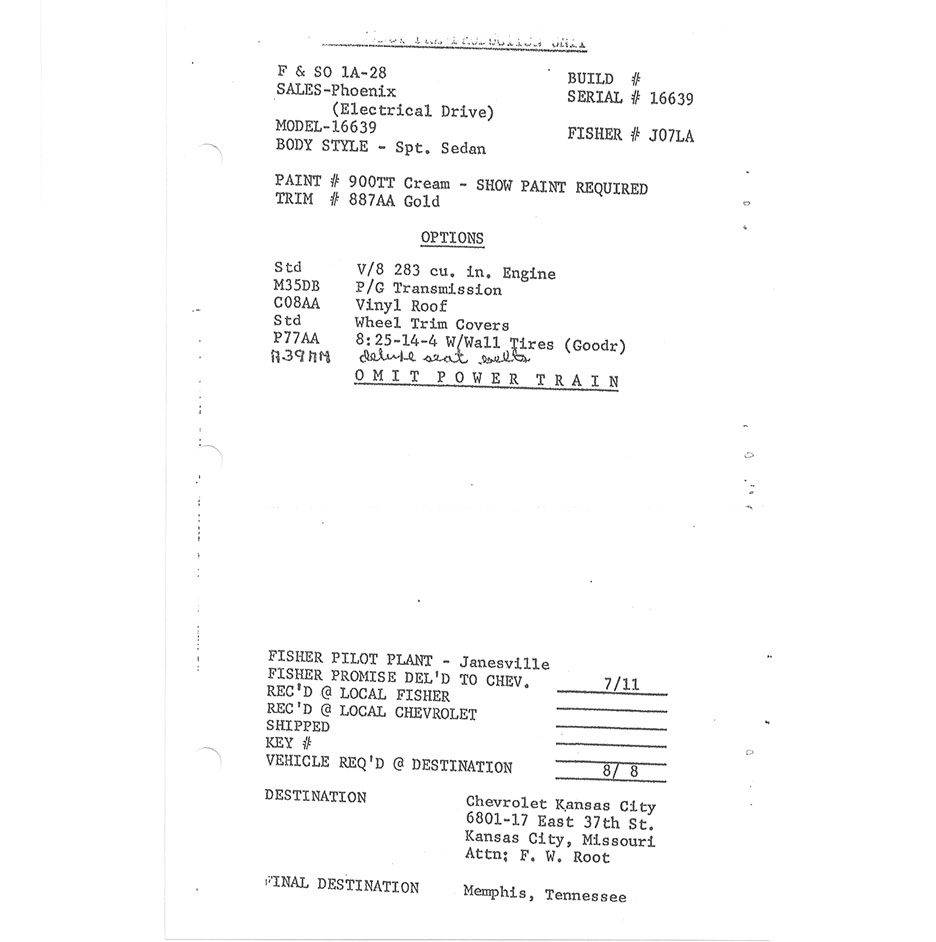

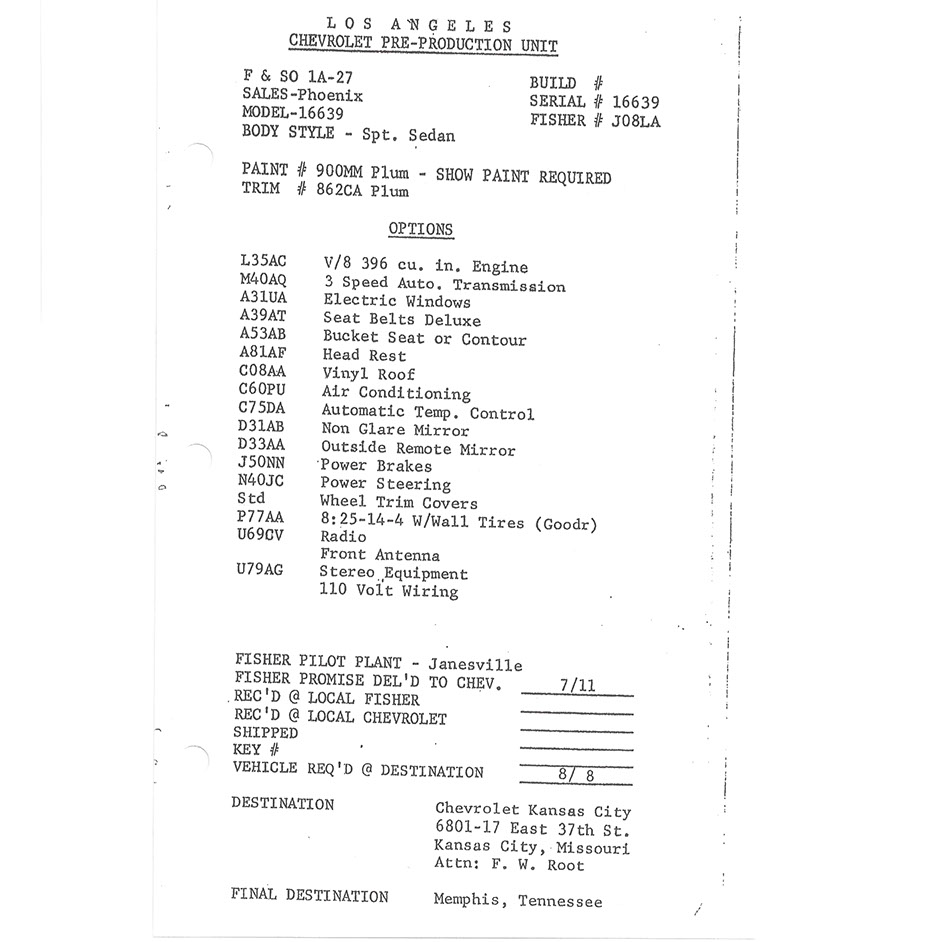

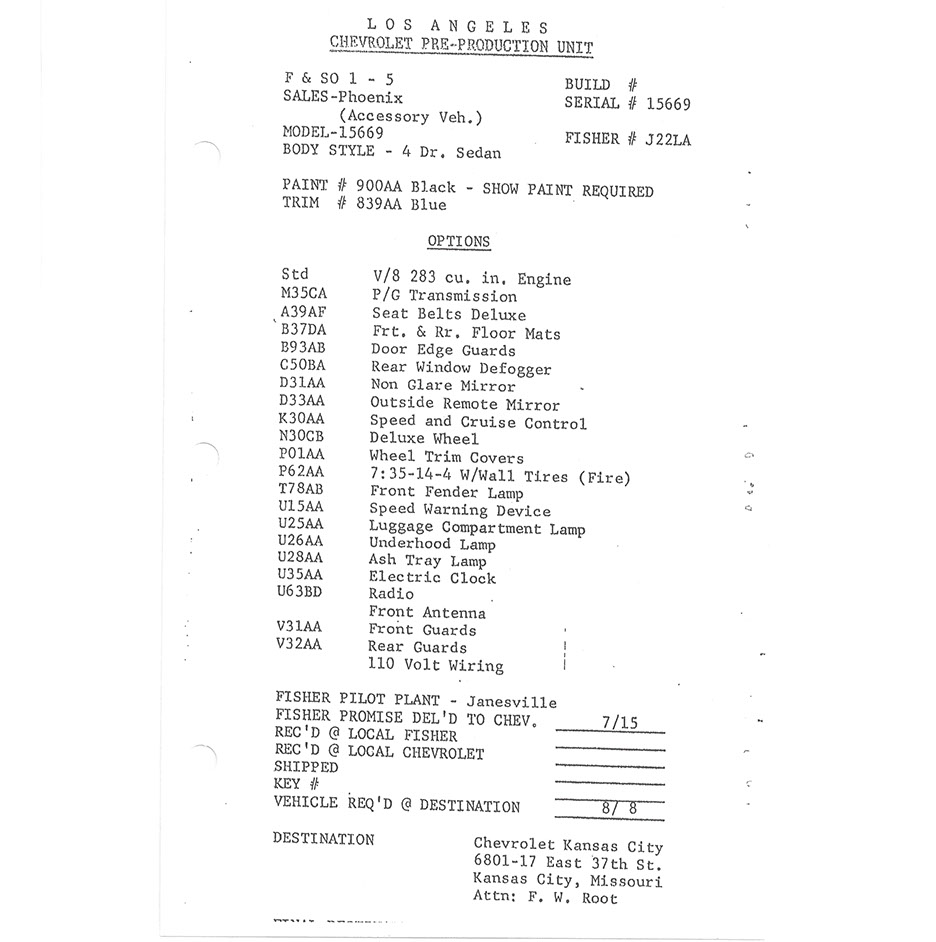

• Model numbers and serial numbers represented body style and engine size.

The forth digit represented body style.

3 = Coupe

6 = Convertible

The third digit represented engine size.

3 = L/6 230 cu. In.

4 = V/8 283 cu. In.

5 = L/6 250 cu. In.

6 = V/8 327 or 350 cu. In.

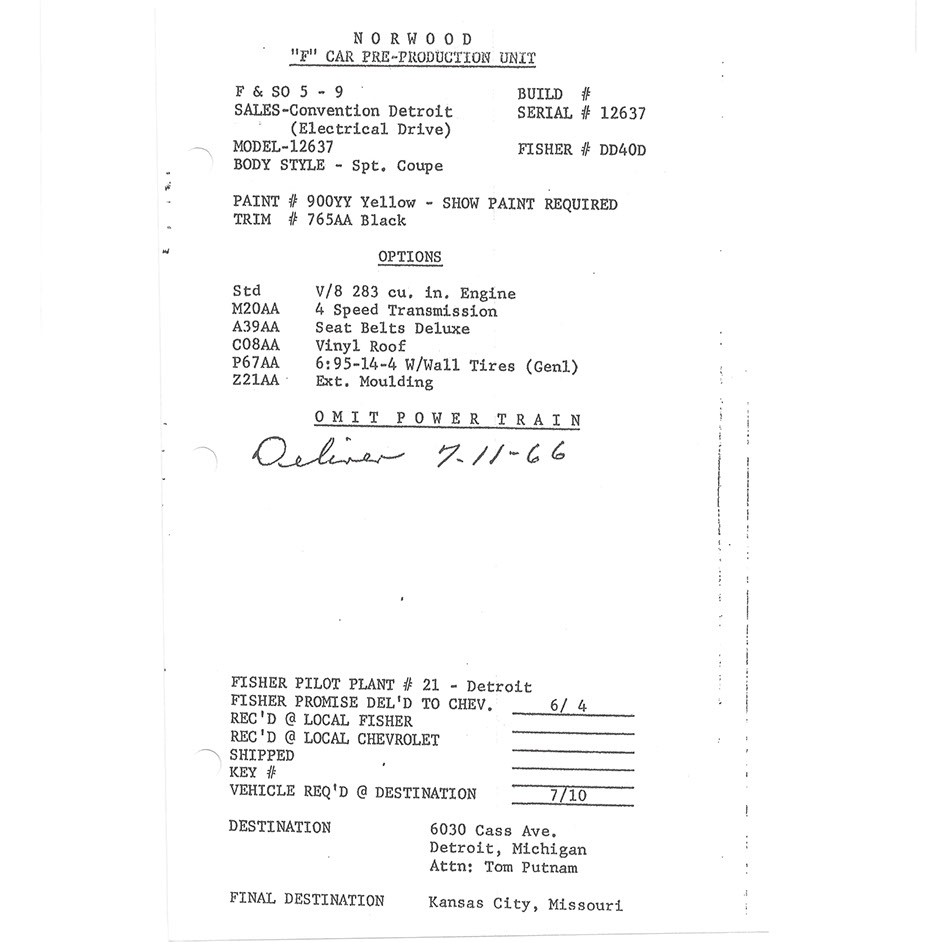

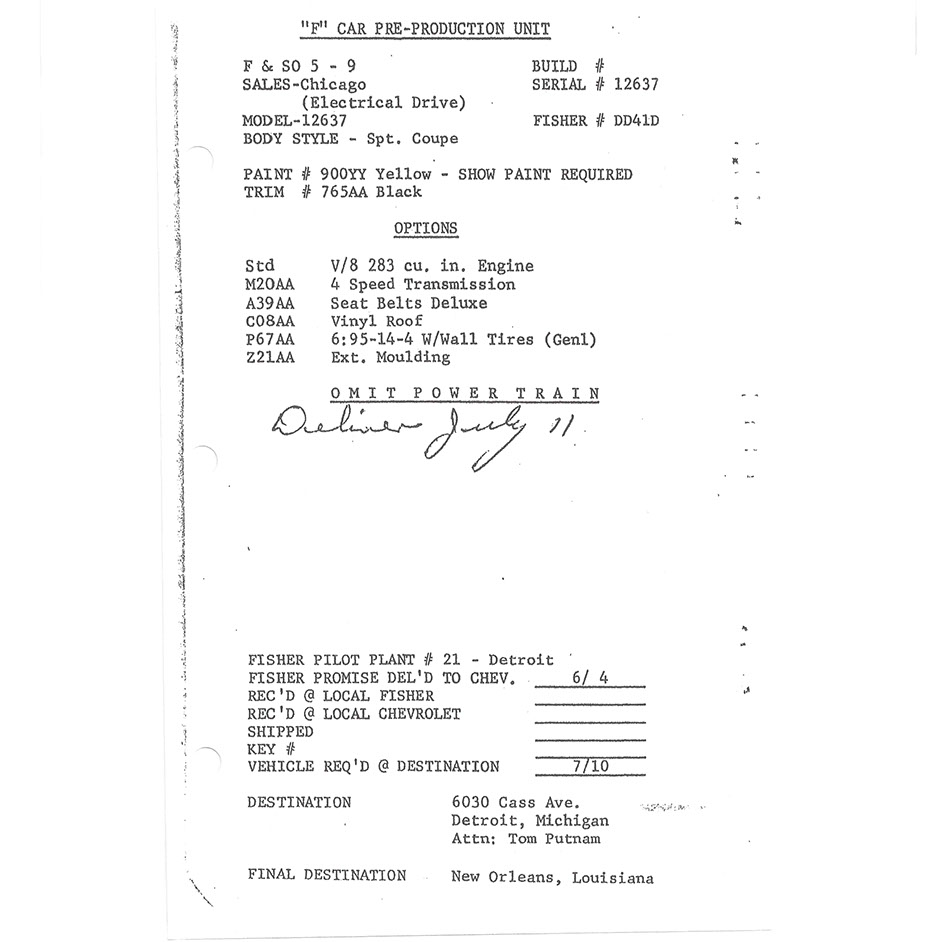

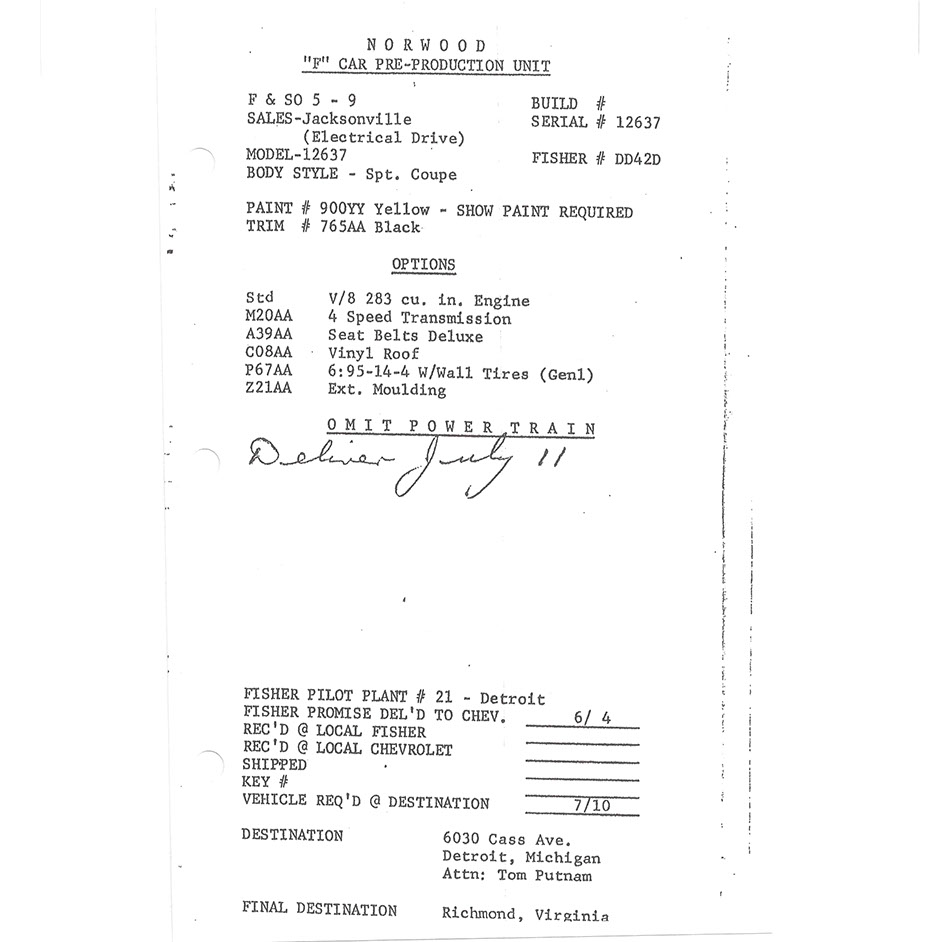

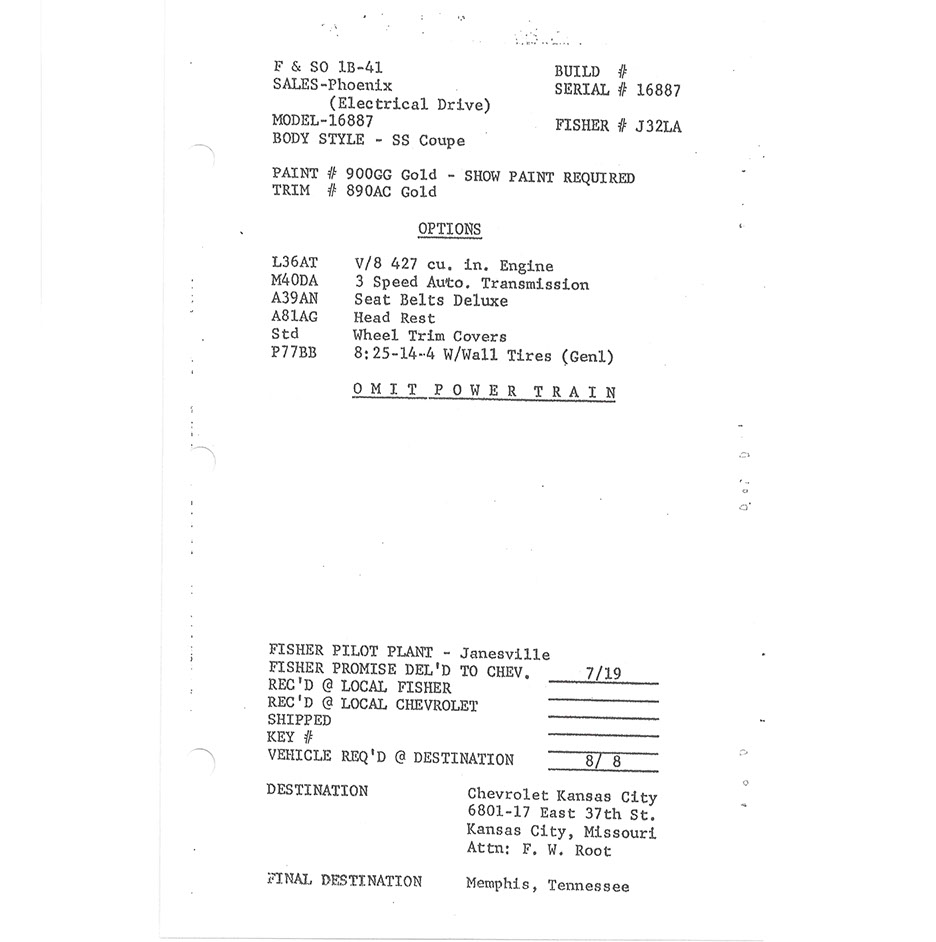

All third digit sixes were stipulated as 327 or 350 in their content configuration. Exception taken only to budgetary manipulation builds where the model and serial number called for a 327 or 350, but a 283 was noted in content configuration. This happens on seven builds…. (1) Export to Canada Car, (1) Crash Safety Car, (1) Corrosion Test Car, and (4) Omit Power-Train Electrical Drive Cars.

For Example: If the intended use is to destroy a car in testing, use the cheapest power-train available. In the case of the Electrical Drive Cars, budgetary compromises were made to make it more cost-effective to achieve their resale after removal of the electric drive was complete.

• Production of F-Body Pilot Prototypes began on or around May 17, 1966 and ended on or around July 20, 1966.

• All Pilot Prototypes still in Pilot Prototype Facility Storage in Norwood on August 1, 1966 were used as assembly line test mules. There was a total of nine builds, all sales convention cars.

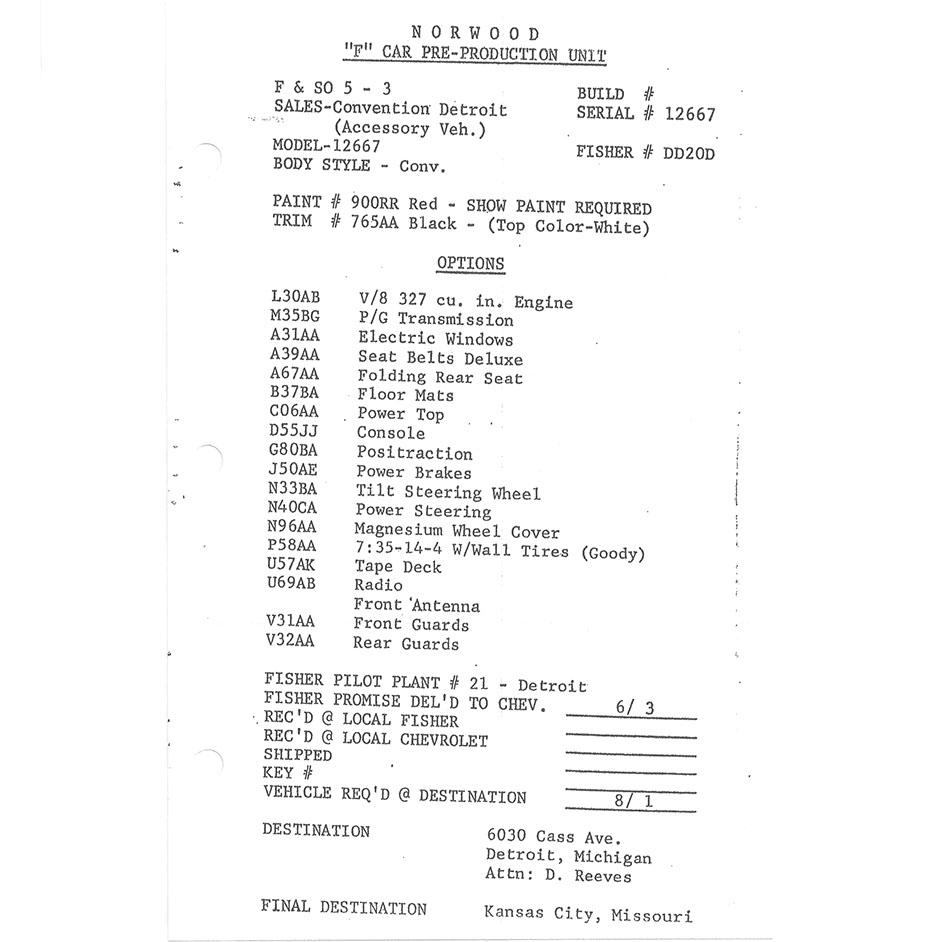

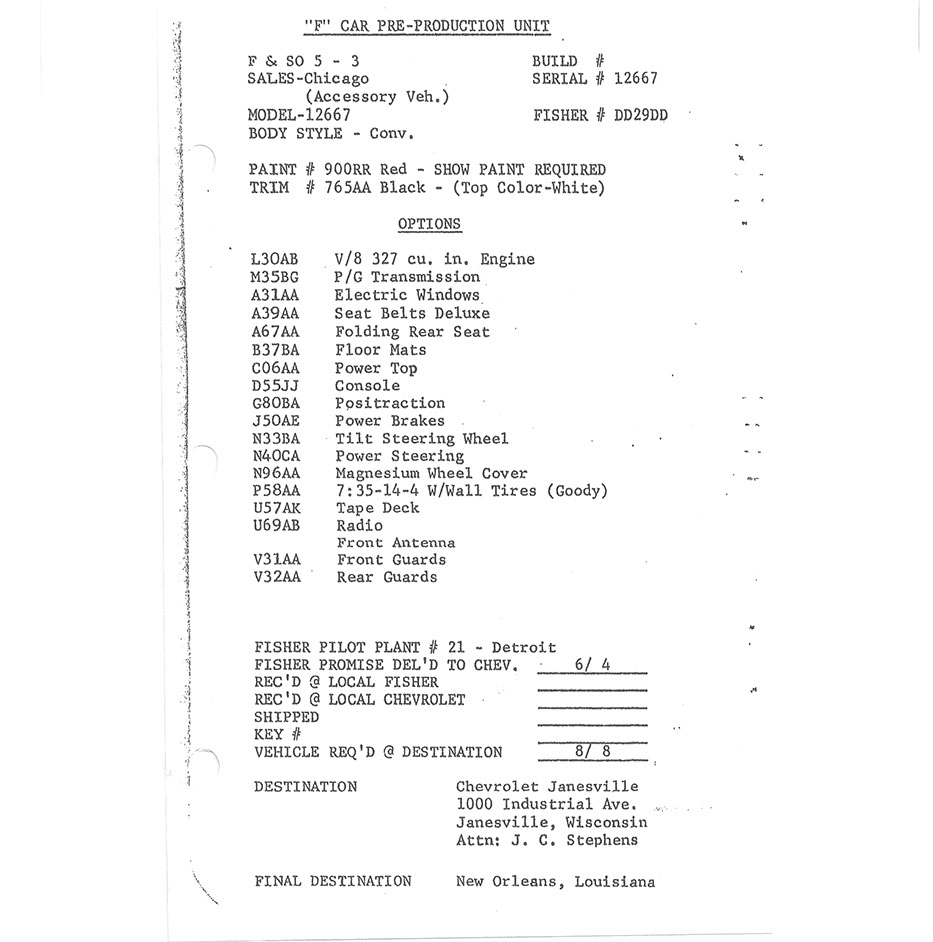

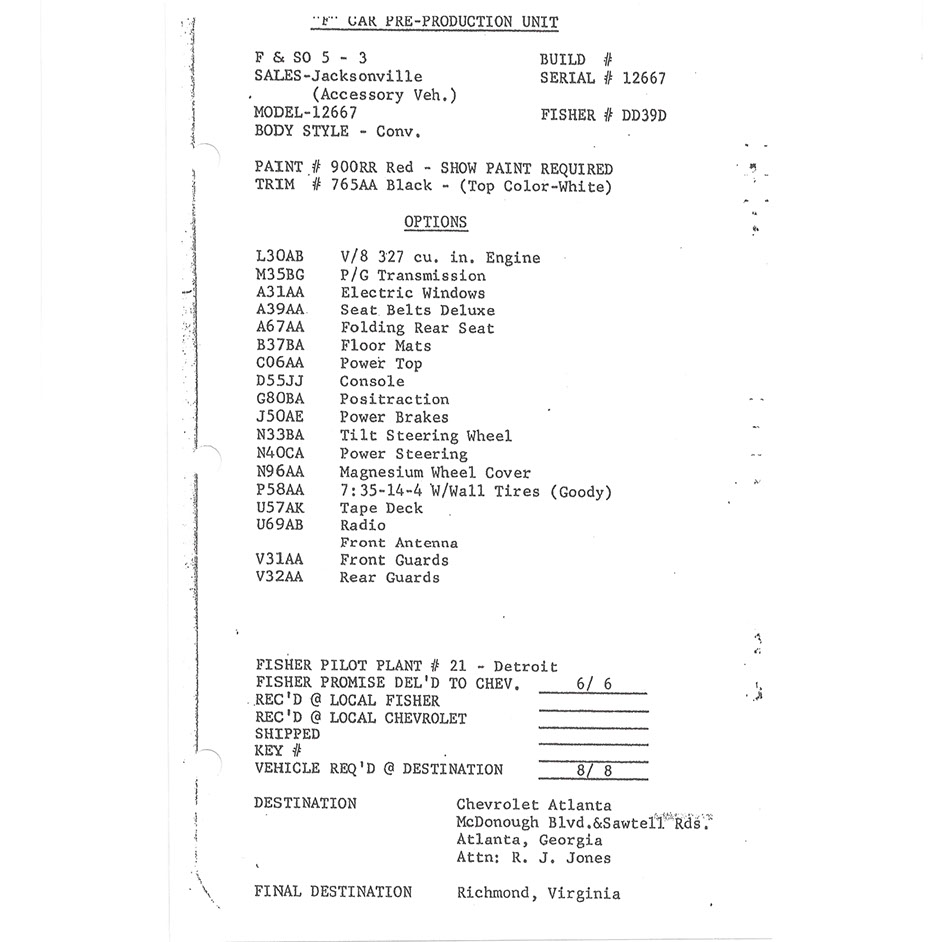

• There were four Pilot Prototypes used at all four Sales Conventions. (1) 6 cylinder, (1) Electro-Maro, (1) 350-SS, and (1) Accessory vehicle. The four Sales Conventions were strategically located in Detroit, Chicago, Jacksonville, and Phoenix.

• The vast majority of the Assembly Information Manual (AIM) changes were accomplished between May and Mid July 1966...Precisely when the Pilot Prototypes were under evaluation via the Hand build methods at Norwood for RPO time study, fitment, and design production accuracy.

• One major purpose of the hand build was related to time studying each individual Regular Production Option (RPO) in advance of production start. For the start of full 1967 production RPO build data for the next production day was key punched on to IBM Punch cards and was then loaded in a batch mode as the IBM 360 main production computer was to be programmed to calculate exactly how long it took to build a unit at both Fisher Body and Chevrolet. This computerized sequencing was intended to predict optimal production sequencing based upon an individual car’s option content- meaning that all of the work to build every aspect of a Camaro first had to be time studied on the Pilot Prototypes first-and then broken down into individual work elements with a time value associated with each individual RPO. At its most basic these elements consisted of a series of left and right hand motions known as “therblngs” or basic divisions of accomplishment. The time needed to build a vehicle with a given option content could vary greatly- and this is where a basic understanding of the importance of line cycle time comes into play. On the Pilot Prototypes the time to install each individual RPO was studied and developed by the work standards engineers along with modifications to the line equipment and verification of the fit accuracy on any second or third tier subcontracted parts and any plant constructed sub assemblies built using those parts.

• The NCRS Certificates confirm our research and interviews that all Norwood Pilot Prototypes Builds were started in consecutive VIN number order. The VIN number order fits precisely with the original unaltered page sequence of the Pilot Book builds with third and fourth digits an exact match.

• All ten cars verified and documented by this website thus far... #1, #7, #10, #13, #28, #29, #31, #36, #46, #49, and LA #3 have Vins that match their pilot page, build configuration, and original shipping geography precisely.

• All ten cars have documented Pilot Prototype tags, Pilot Prototype markings, and prototype parts.

• All ten cars have sheet metal stampings that don't exist on production cars, but match all existing Pilot Prototypes.

• All ten cars are hand welded... not robotically welded.

• All ten cars have date coded components as early as March of 1966.

• All ten cars were built with many prototype parts without part numbers. Part numbers were inscribed in these parts with marker and an engraving scribe. Additionally, these cars were equipped with Pilot Prototype tags, and Pilot Prototype stickers.

• All ten cars have historical title histories obtained.

• All intended end uses for the F-Body Pilot Prototypes have been ascertained and are reflected in their commonly held names at the top of each car’s individual research page.

• As of 3/1/2015, ten F-Body Pilot Prototypes are confirmed to still exist. However, research is still on-going.

• The Pilot Program was intended as an Engineering Study with many smaller studies within the larger study.

• One of these smaller studies was the study of the IBM 360 computer driven by the punch cards for each individual build. As one would expect, testing of this computer was incorporated into this process. Consequently, many cowl tags created were done as a test of this cutting edge computer. A very high concentration of cowl tag test runs were present on the Sales Convention Cars.

• Space became an issue in the Norwood Pilot Prototype Facility very early on. This became the secondary issue with the cowl tags. At approximately build number N100010, it became impossible to pull the Fisher Body Coaches in the same order they were received. Pilot Line Employees were instructed to treat the coaches as sub-contracted parts and pull them at their convenience in an order that was time efficient… closest first. This created the final anomaly to the trim tags.

• These two issues, answered with the boisterous laughter of employees and management in interviews has finally been documented and proven. Special thanks from the Hobby to all these men who shared their memories in solving this dispute.

• All ten Pilot Prototypes Trim tags have now been verified to factory records and are an exact match, to and include, body numbers.

• Asterisks, as they appear in the Pilot Book, denote builds with air conditioning.

• NCRS certificates have proven invaluable research tools for the Pilot Prototypes. In some cases, providing the necessary breadcrumbs to confirm the existence of a car in present day. To this end, they also spot-light the inefficiencies of GM paperwork in a hand-built, non-assembly line format. This is showcased by all forty-nine builds having the exact same “Official Production Date” of 8-10-1966. Our research concluded that this date became an afterthought until a time that shipping invoices became necessary. It was at that moment that all forty-nine dates were inputted in entirety, with the date being arbitrary, but sensible for general production from the standpoint of the shipping clerk.

• Thirty-seven Zone "0" cars were slated for use as "brass hat" or "executive" cars... with destruction afterwards part of the planning process, but not without exception.

• Twelve remaining cars were slated for use by divisions of Sales.

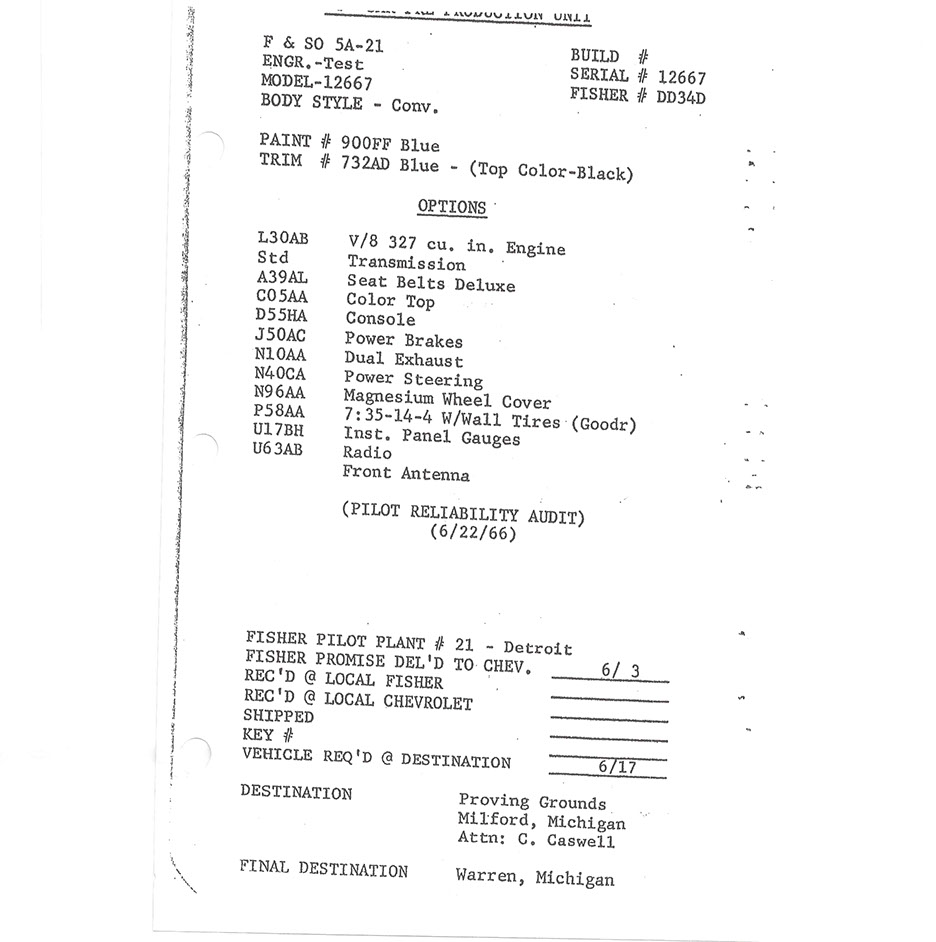

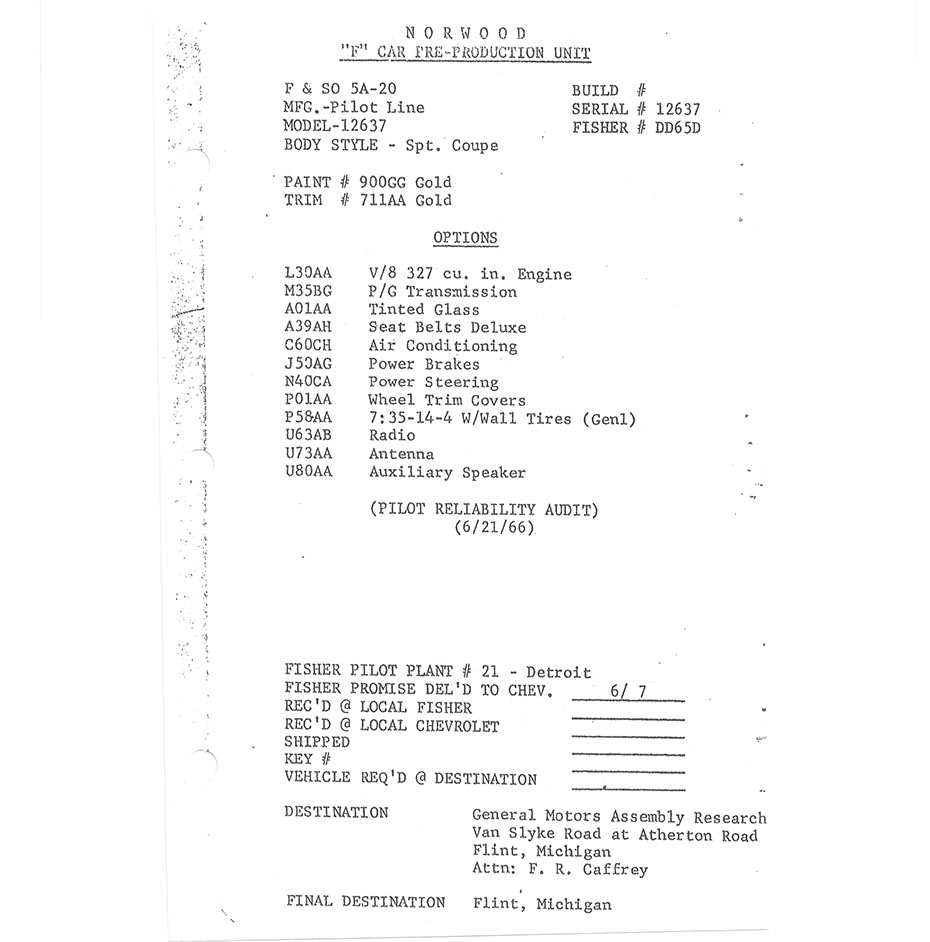

• Pilot Reliability Audits (See Pilot Reliability Button On Homepage)

• Twenty-seven Fleet and Special Orders were executed for the F-Body Pilot Prototypes.

(21) One of One

(9) One of Three

(8) One of Four

(11) One of Eleven

• Only twelve of the fifty-two NCRS Certificates gleaned any “Dealer Ship To” information.

•Of the twelve, ten of the twelve cars were used by sales divisions. 100% if accounted for on domestic basis only.

• Handwritten notes in the circulated copies of the F-Body Pilot Book were done at the hand of the owner, Jim Seim, Pilot Program Coordinator in 1966. His propensity for “taking his work home” with him, is the reason that this program finally became factory documented.

• Fleet and Special Order Divisional Origins

(13) Sales Convention Pilot Prototypes

(10) Engineering Testing Pilot Prototypes

(7) Engineering Body of Design Pilot Prototypes

(8) Manufacturing Pilot Prototypes

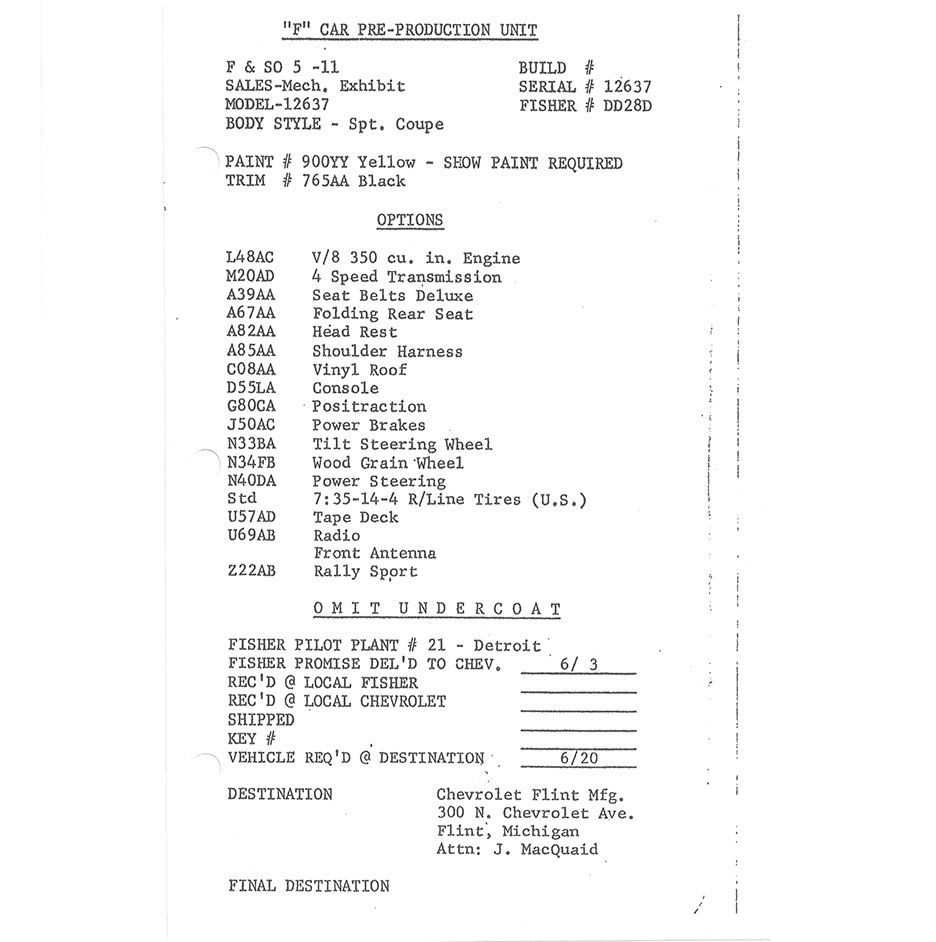

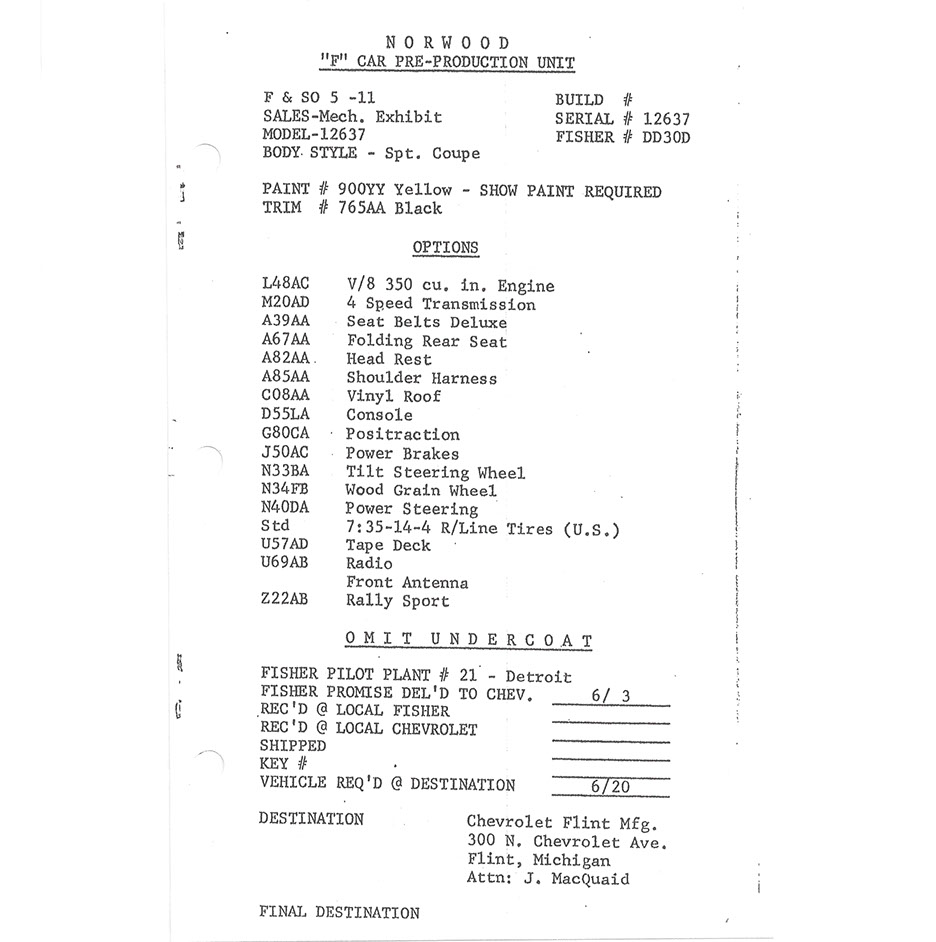

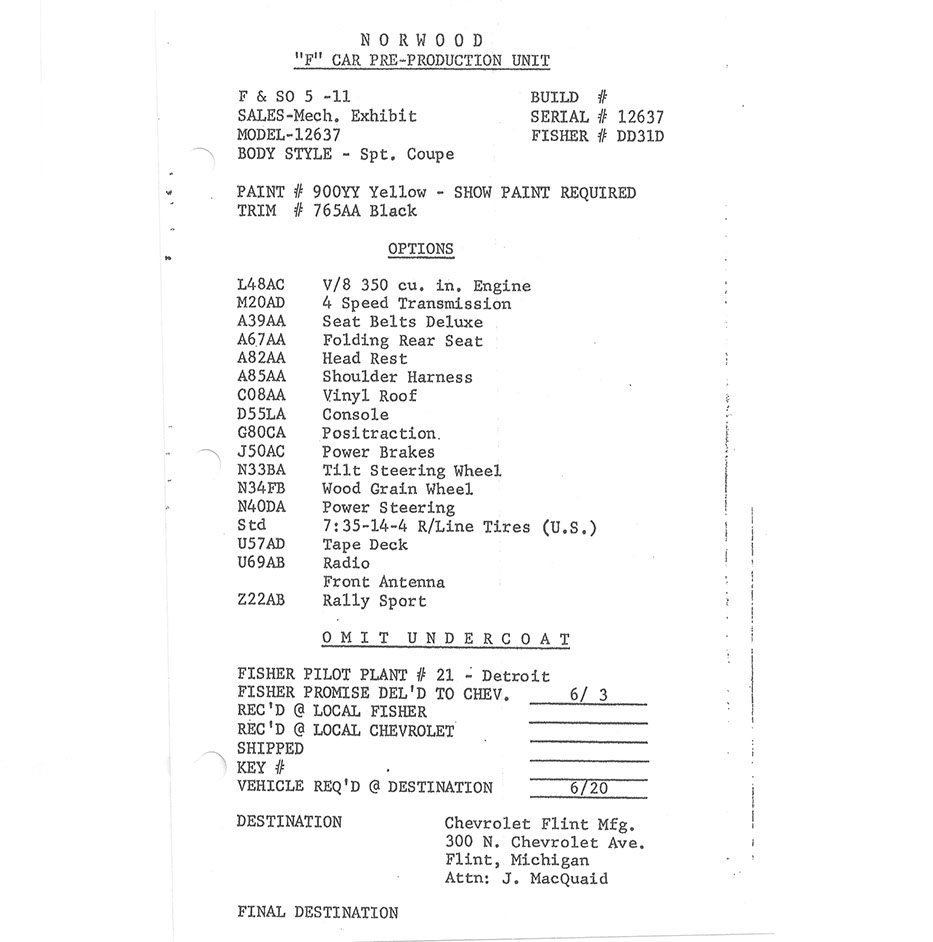

(11) Sales Mechanical Exhibit Pilot Prototypes

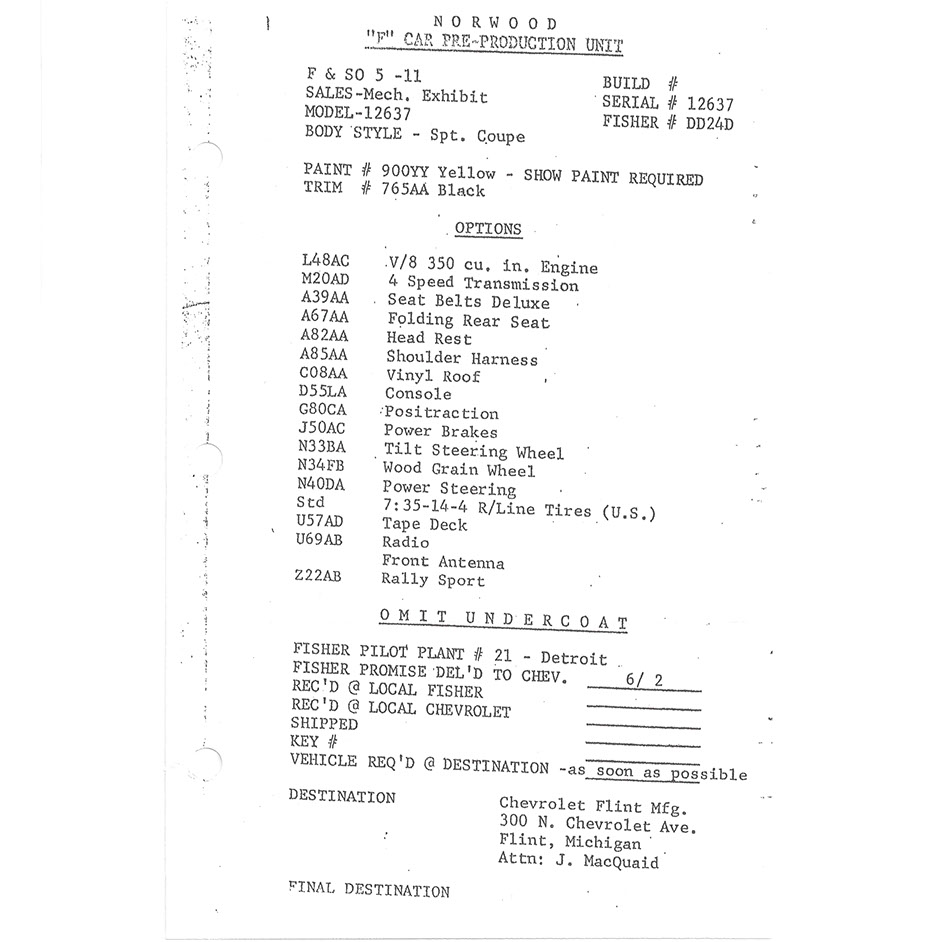

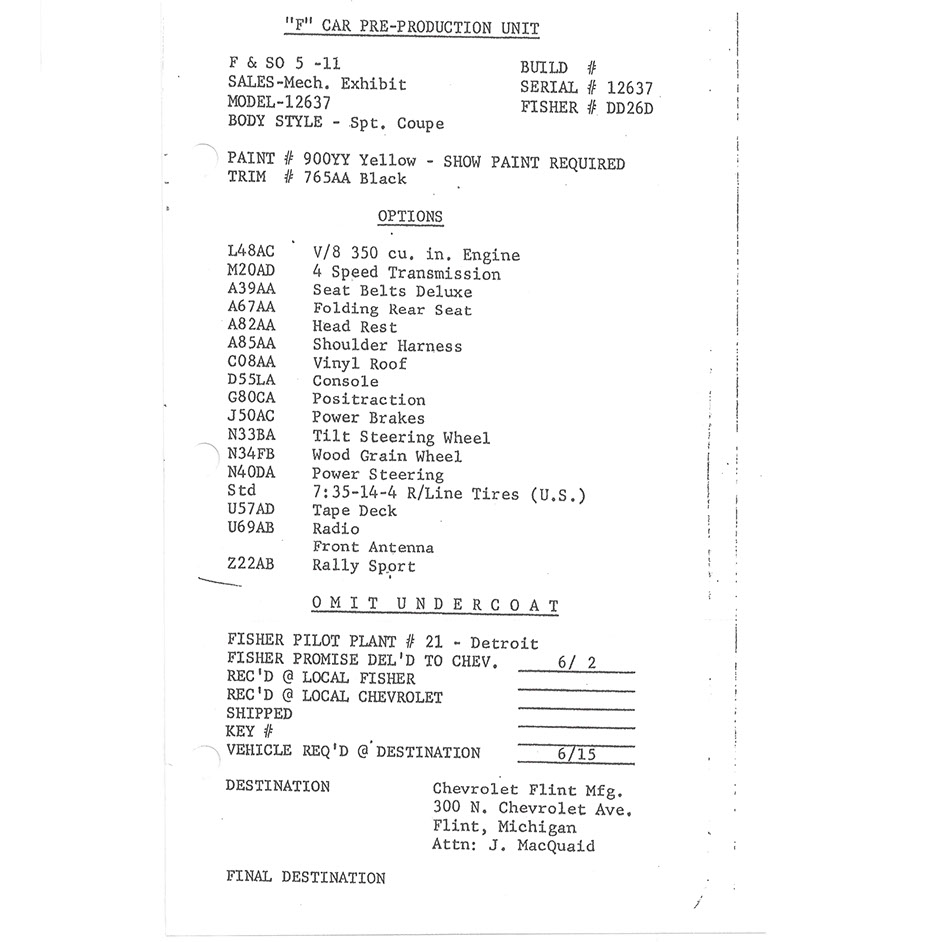

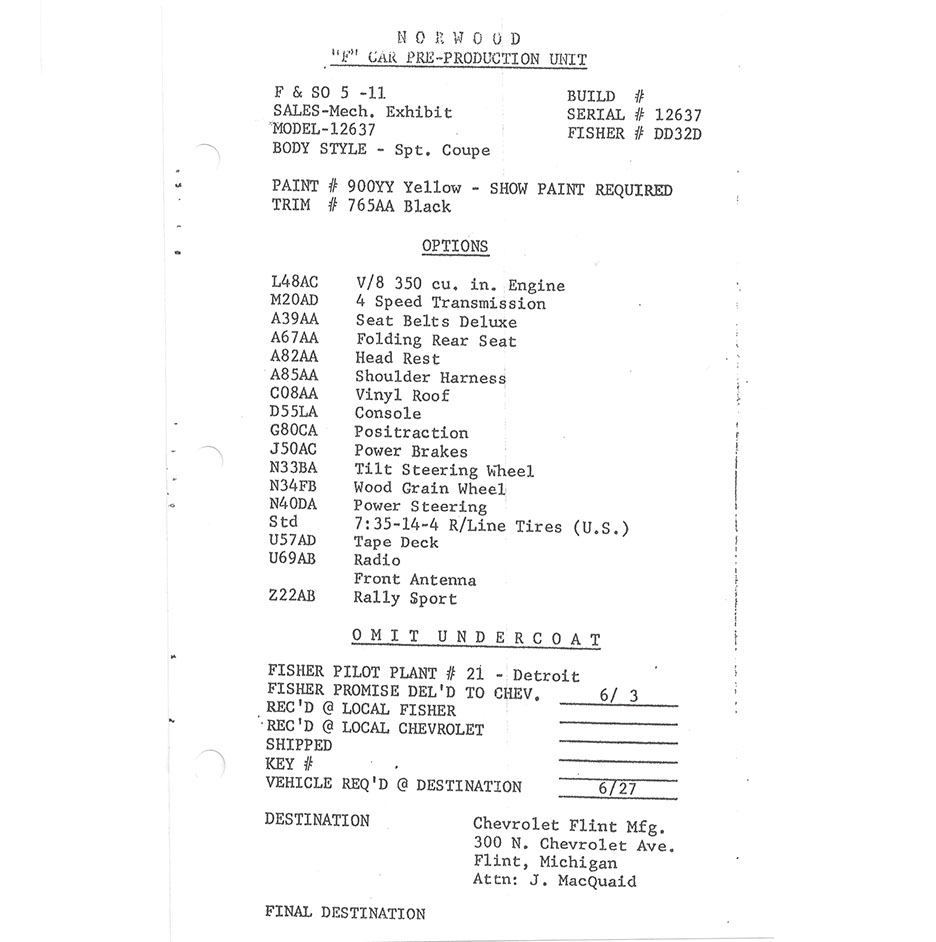

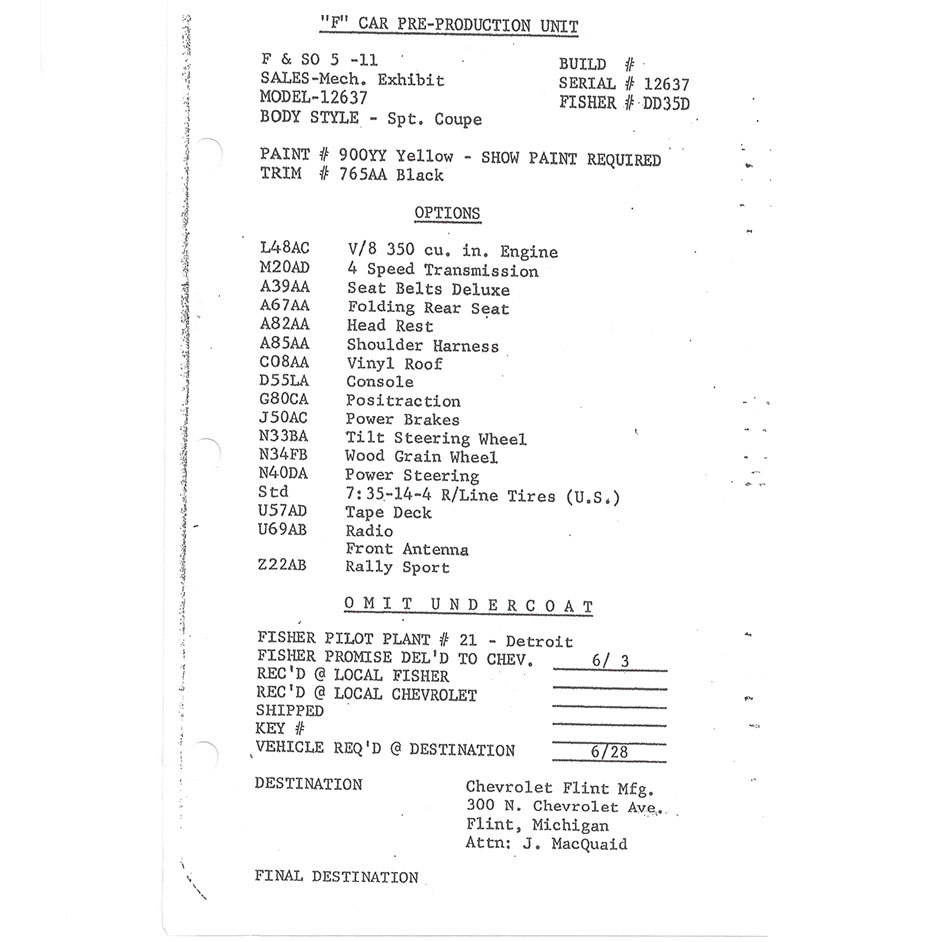

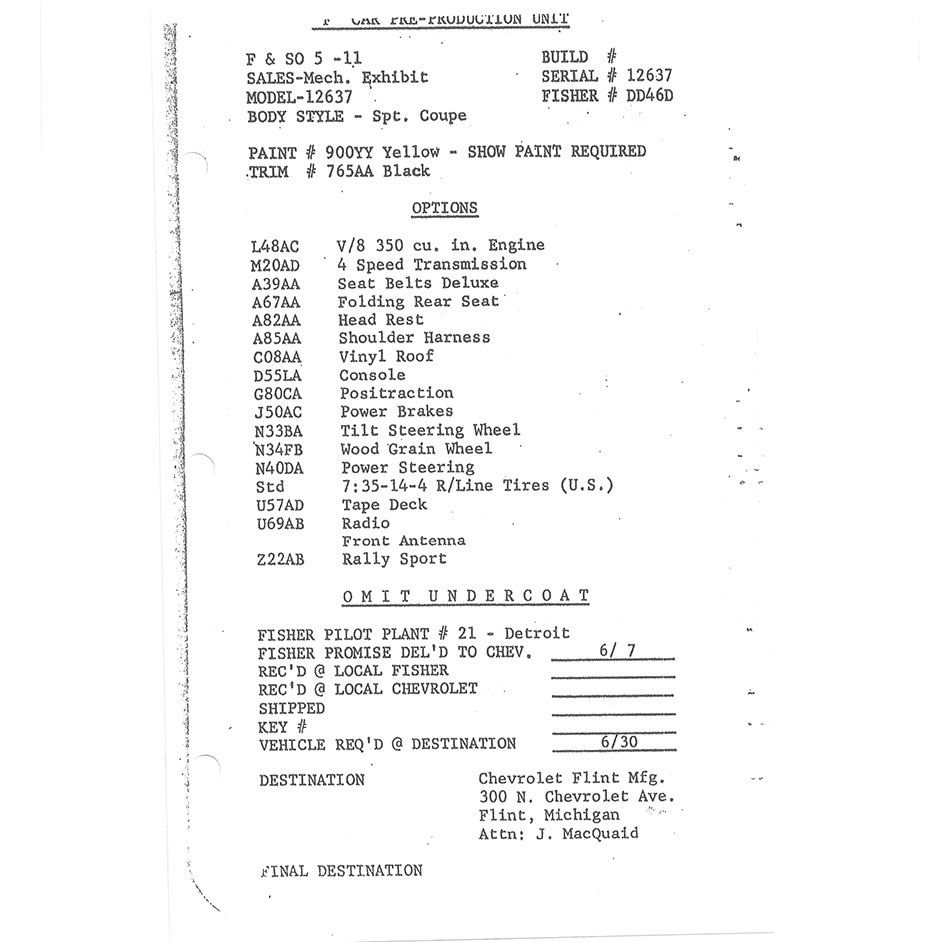

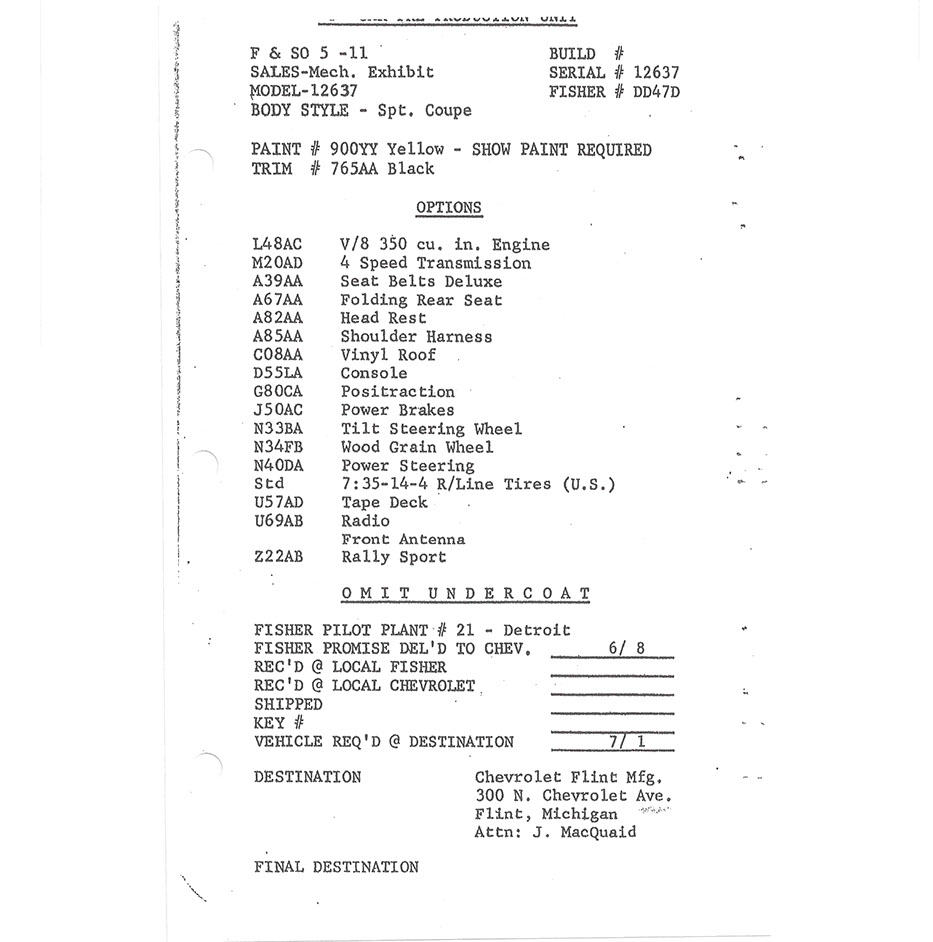

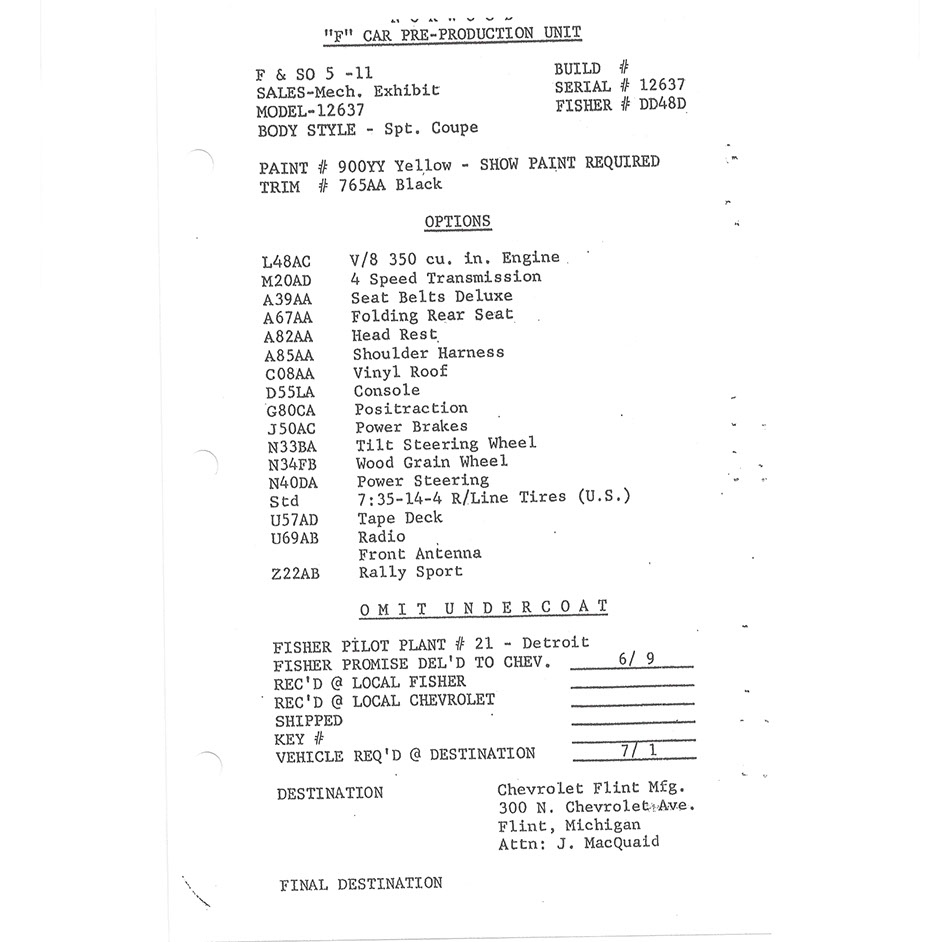

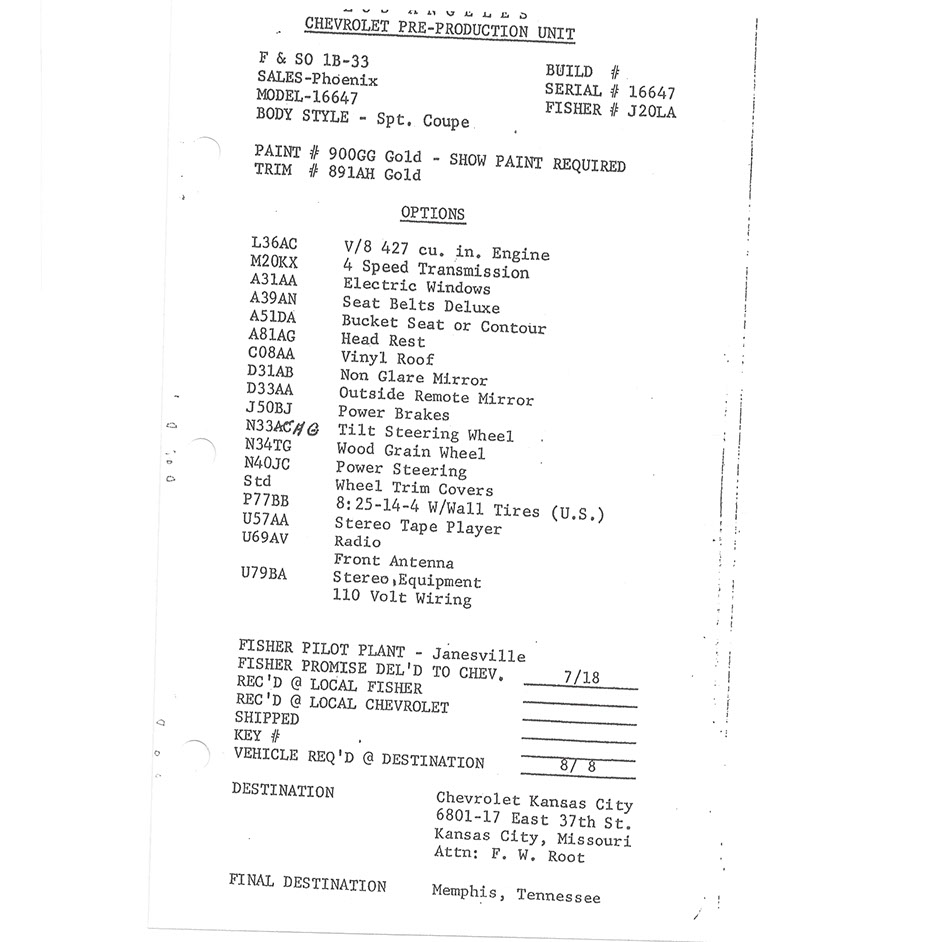

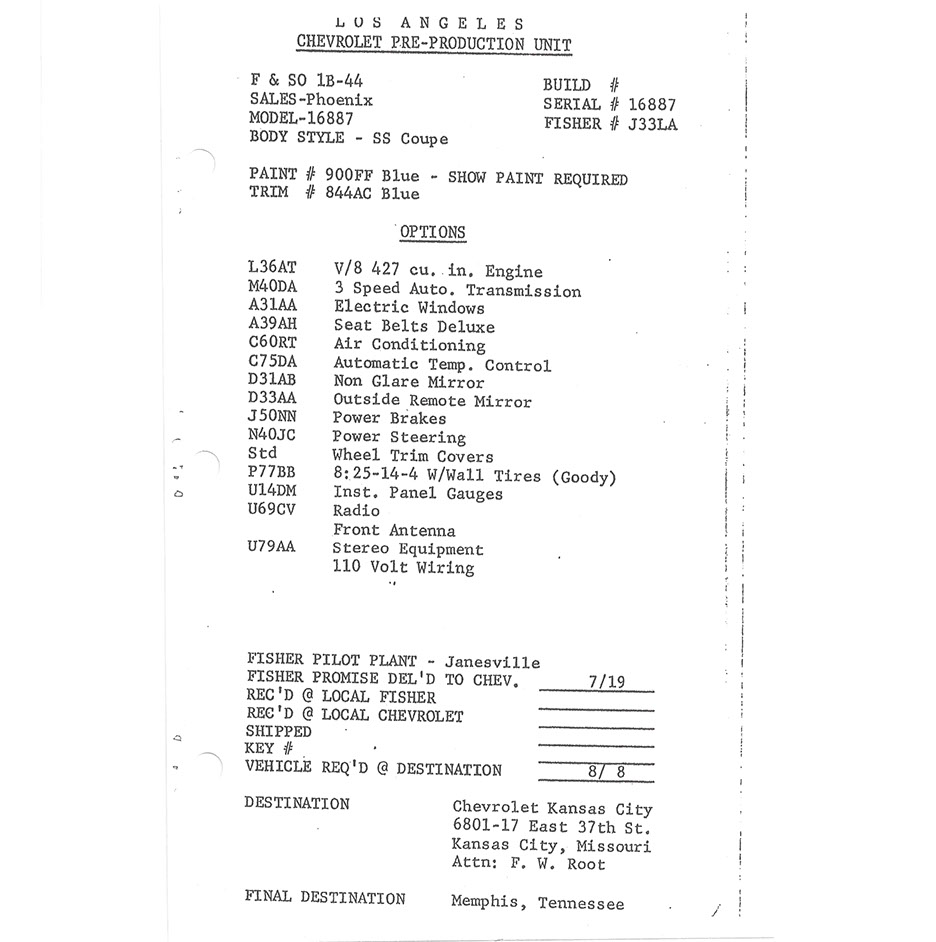

• “Show Paint Required” denoted vehicles that were intended for use in the GM Jam Handy Video, Tech Center Photo Shoots, Magazine Photo Shoots, Television Commercials and Sales Conventions.

• Filming of the latter portions of the General Motors Jam Handy Video began on or around August 10, 1966 and concluded approximately two days later. It was an invaluable photo and documentary resource with Bob Lund of General Motors as a guest narrator.

• Some period photos used on this site were obtained from the General Motors Heritage Center archives.

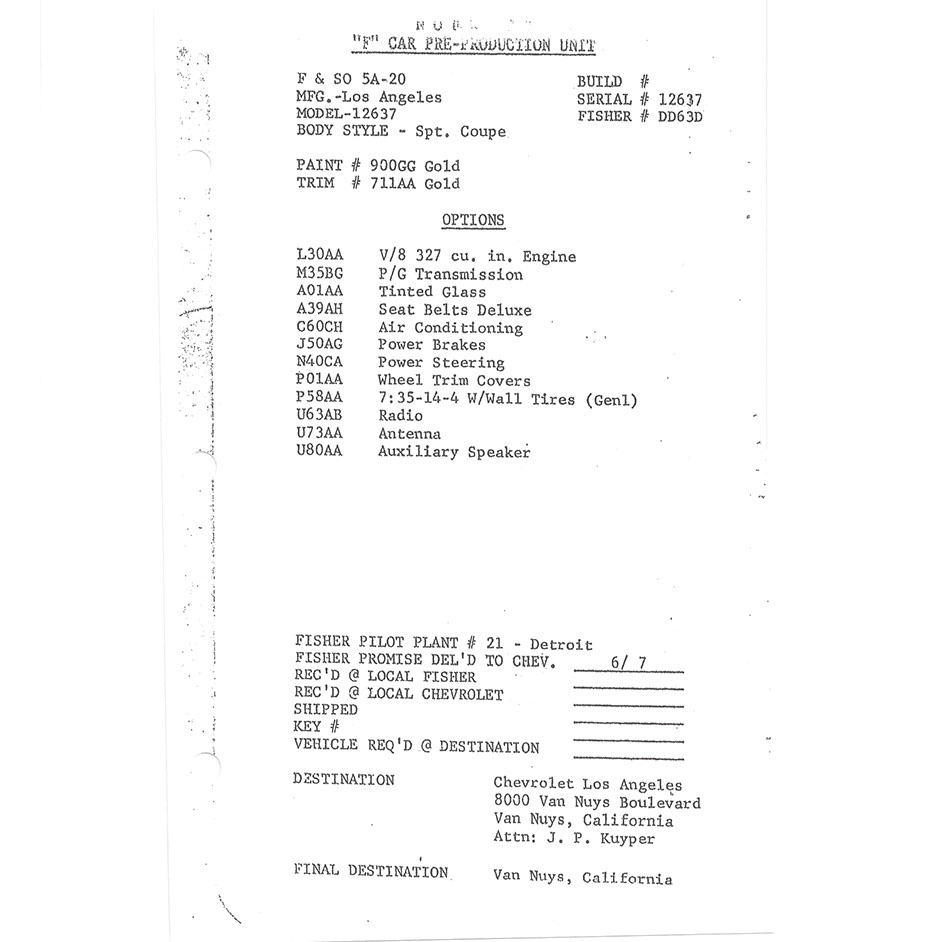

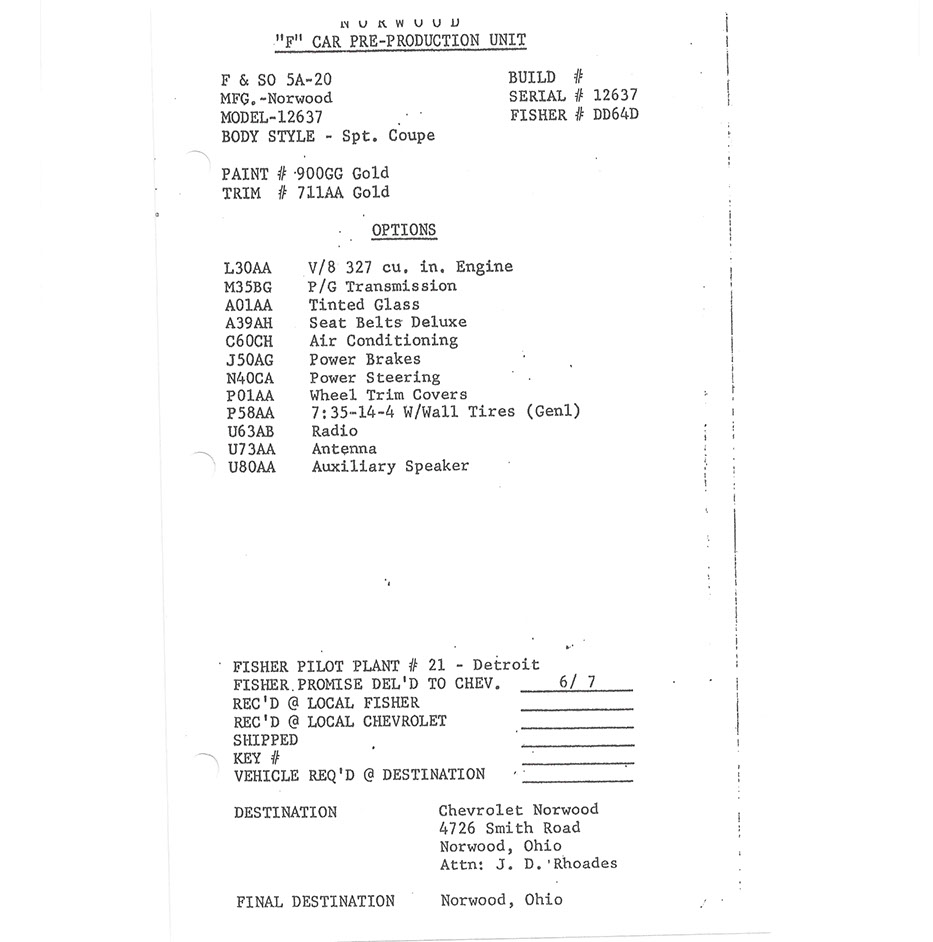

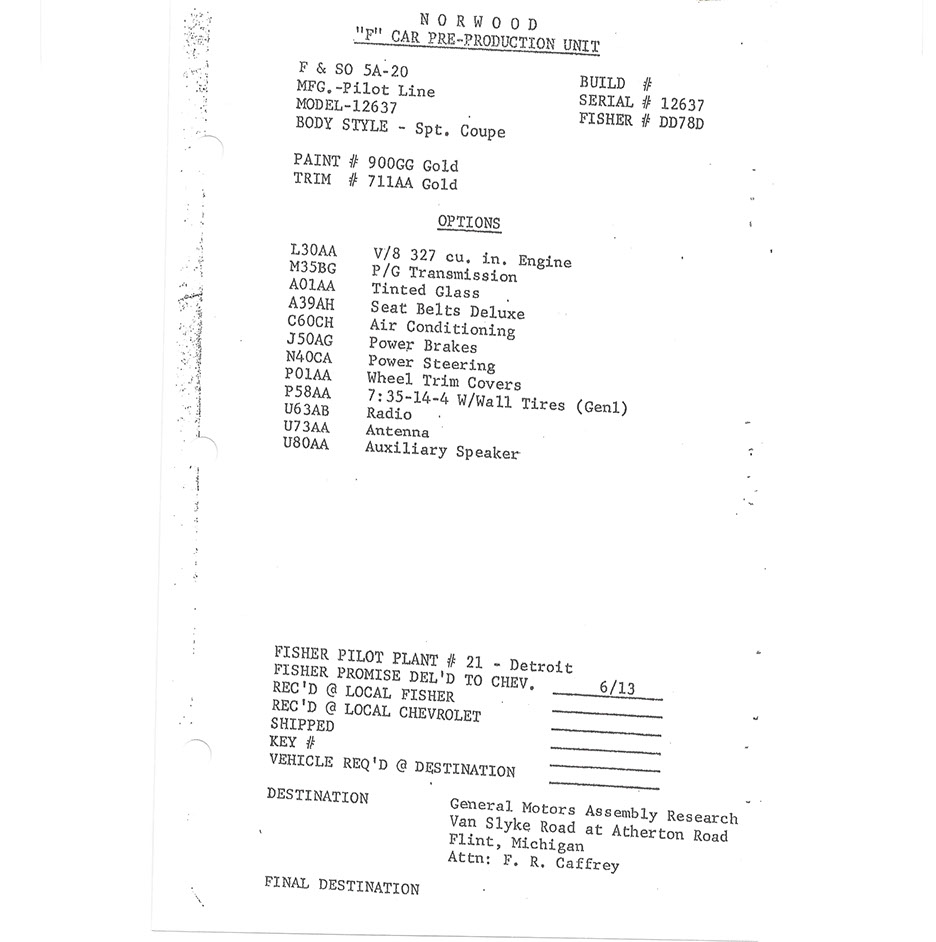

• Colors - Granada Gold - (9)

Marina Blue - (4)

Ermine White - (2)

Mountain Green - (1)

Tuxedo Black - (2)

Butternut Yellow - (16)

Deepwater Blue - (1)

Bolero Red - (6)

Royal Plum - (1)

Sierra Fawn - (1)

Emerald Turquoise - (1)

Tahoe Turquoise - (4)

• Engine Configurations- 230’s - (7)

250’s - (2)

283’s - (9)

327’s - (14)

350’s - (17)

• Transmission Configurations- 3 Speed - (8)

4 Speed - (22)

Power-Glide - (19)

• Tire Sizes - 6.95 X 14 Whitewalls - (13)

7.35 X 14 Redlines - (17)

7.35 X 14 Whitewalls - (19)

• Tire Manufacturers - (5) General, U.S. Rubber Co., Goodrich, Goodyear, and Firestone.

• (13) Norwood Pilot Prototypes were equipped with Air Conditioning.

• Hubcaps - (5) Different styles of Steel Wheels with different hubcaps, center caps, or beauty rings.

• (2) Norwood Pilot Prototypes were equipped with Smog Equipment.

• Delivery Addresses and Contacts, # of Builds (See Pilot Book Address And Biography Buttons On Homepage).

• (13) Norwood Pilot Prototypes equipped with High-Performance configurations.

Coupes - (12)

Convertible - (1)

• Individual essays for each build are present on each individual Pilot Prototype Page.

• This Research Comprised:

5 Researchers

12,000 Hours of research

5 Trips to General Motors Heritage Center

3,000 Hours of phone calls

20,000 Text messages

2,100 Dollars of postage

72,000 Miles of travel

6,667 Files of independent research

100's of personal interviews

7 Years

56,400 Megabytes of research

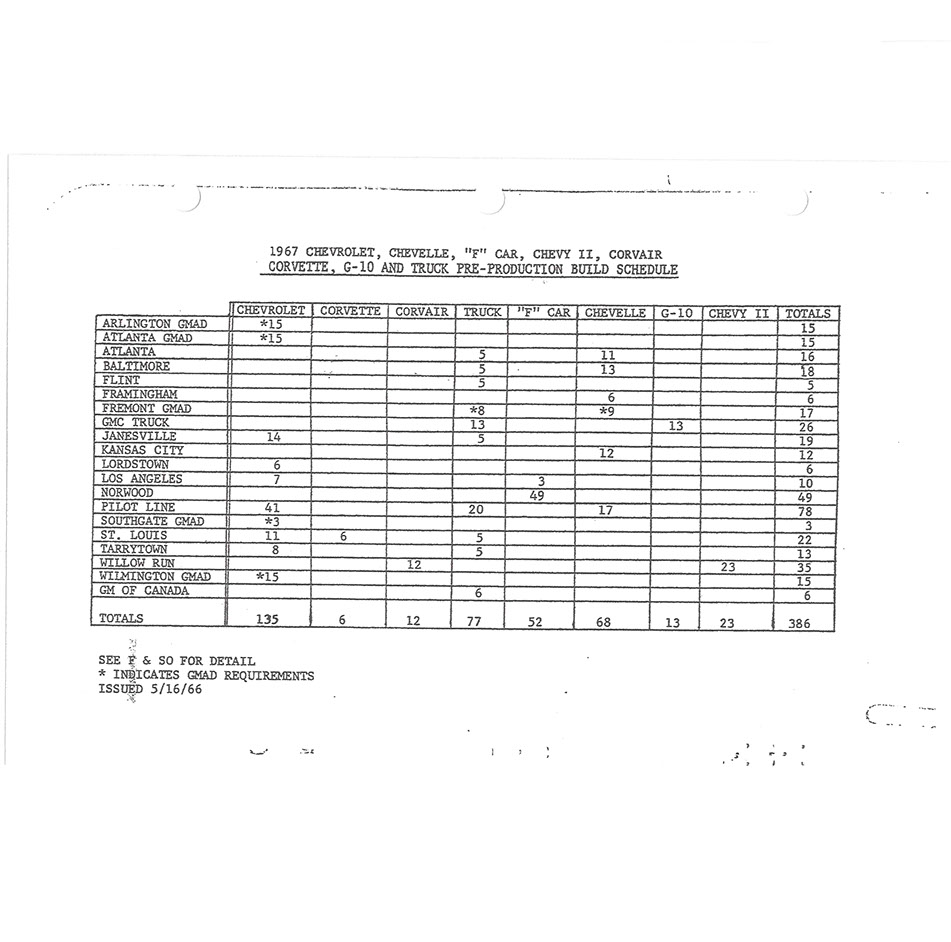

Pilot Prototype Distribution Spreadsheet

Click The Image To Read

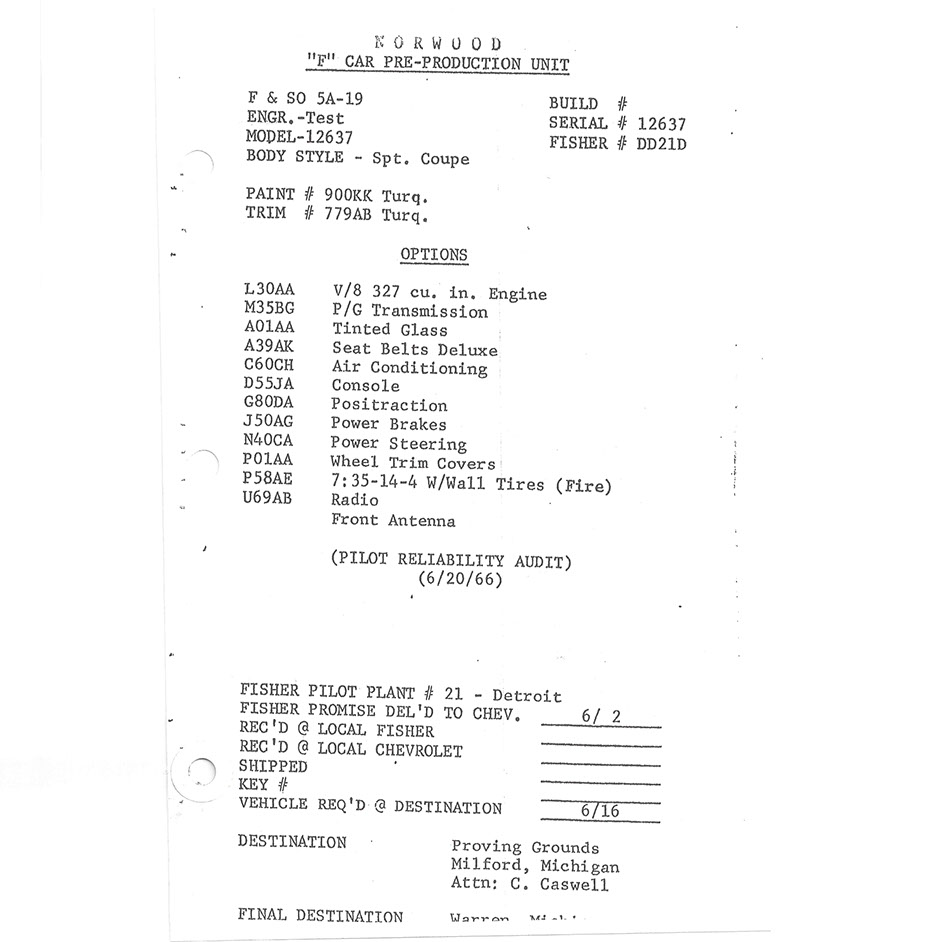

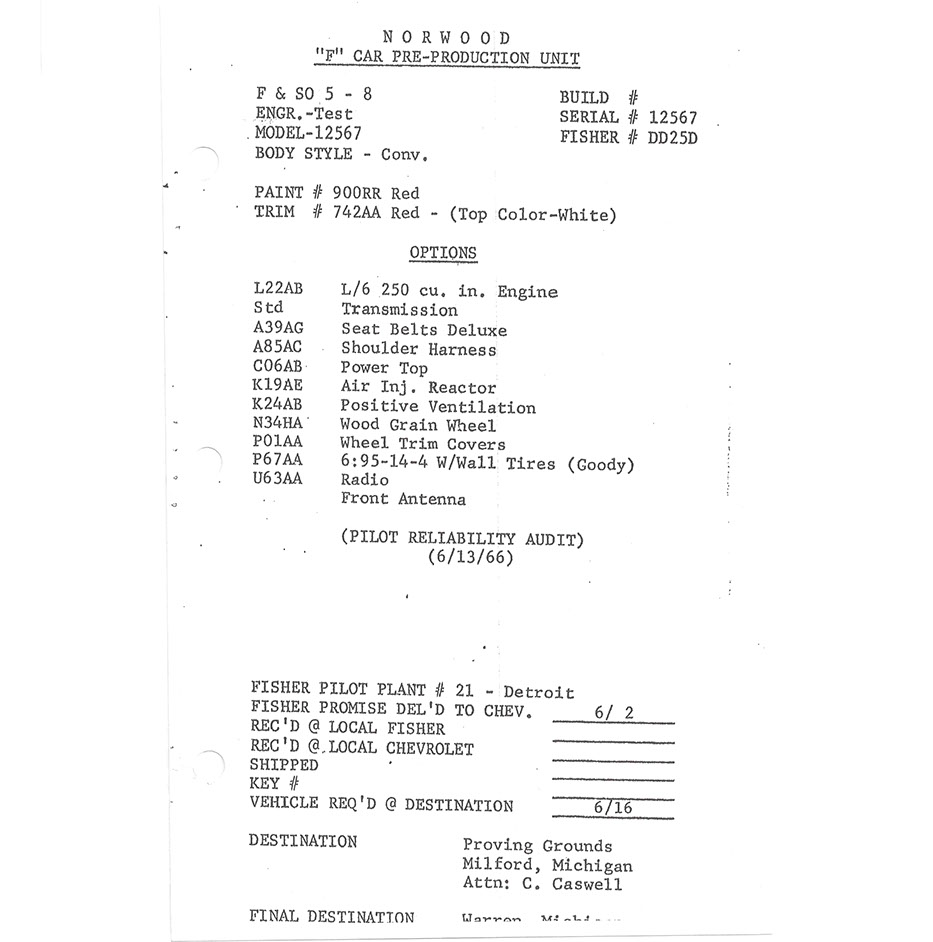

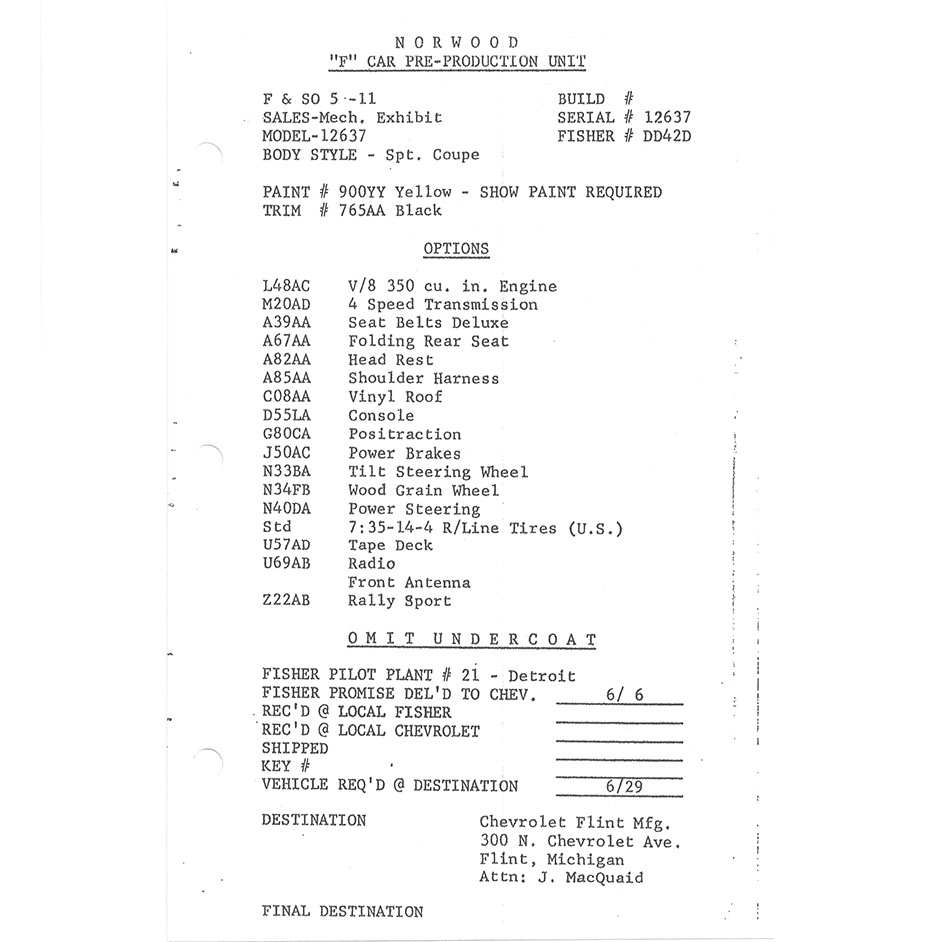

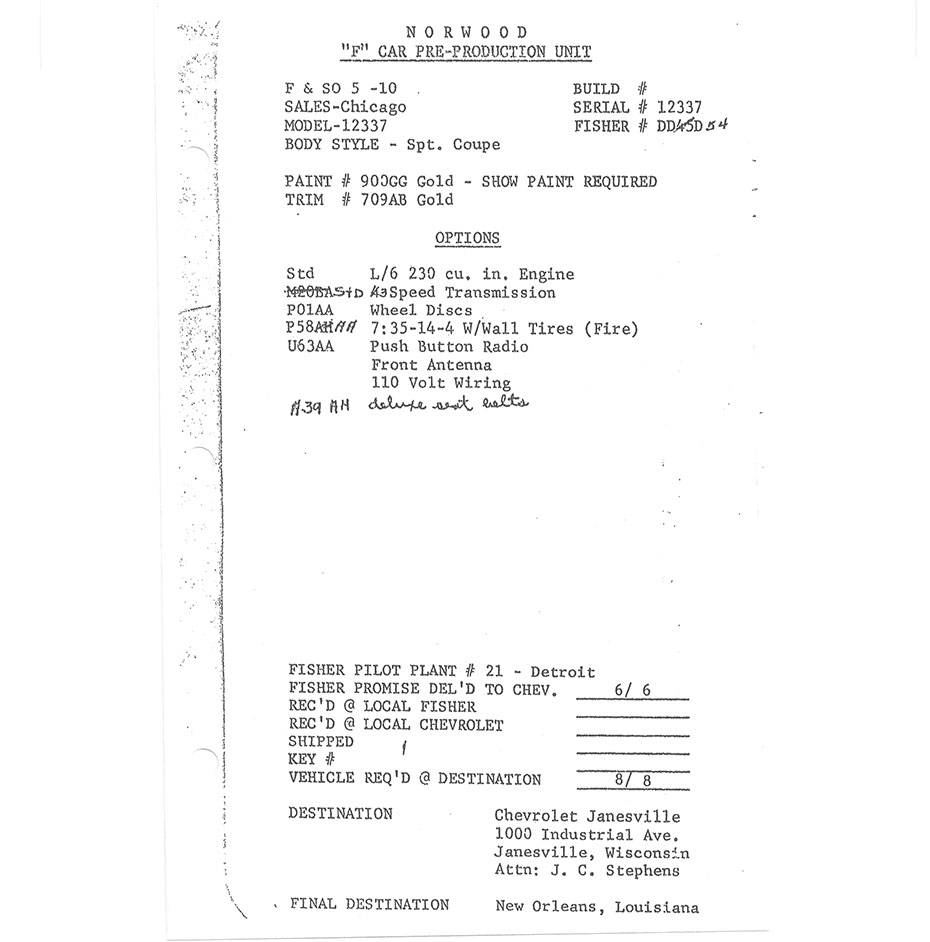

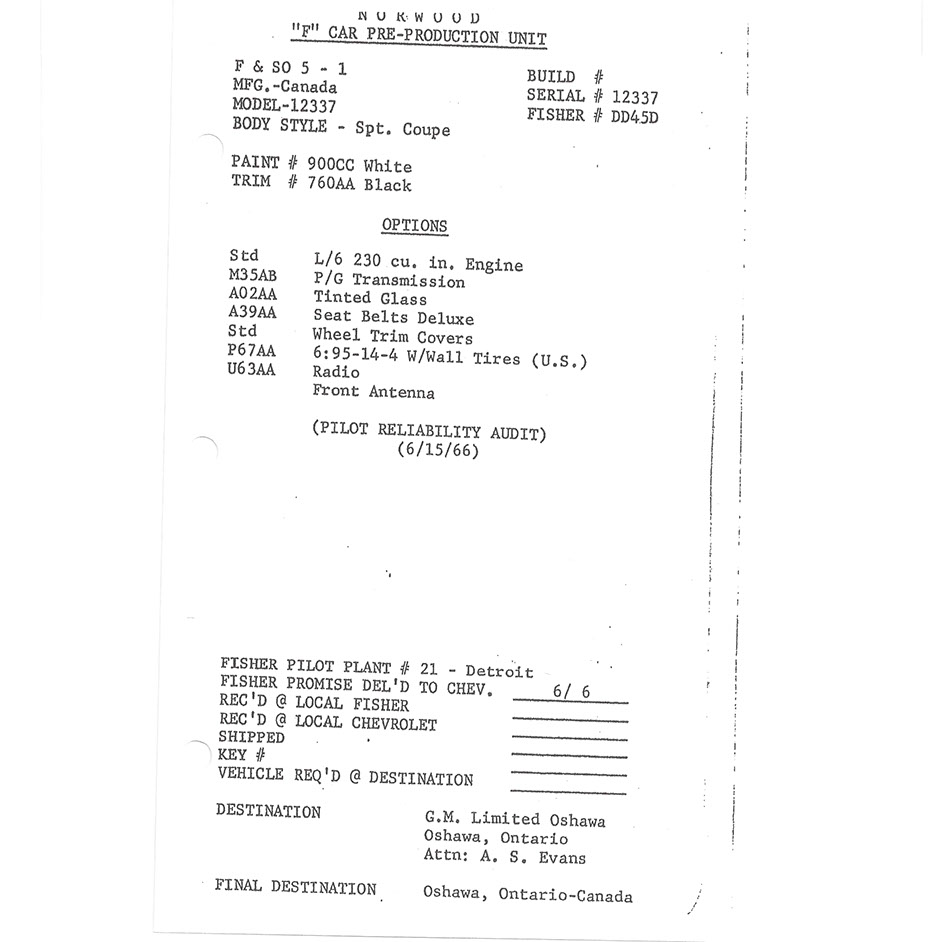

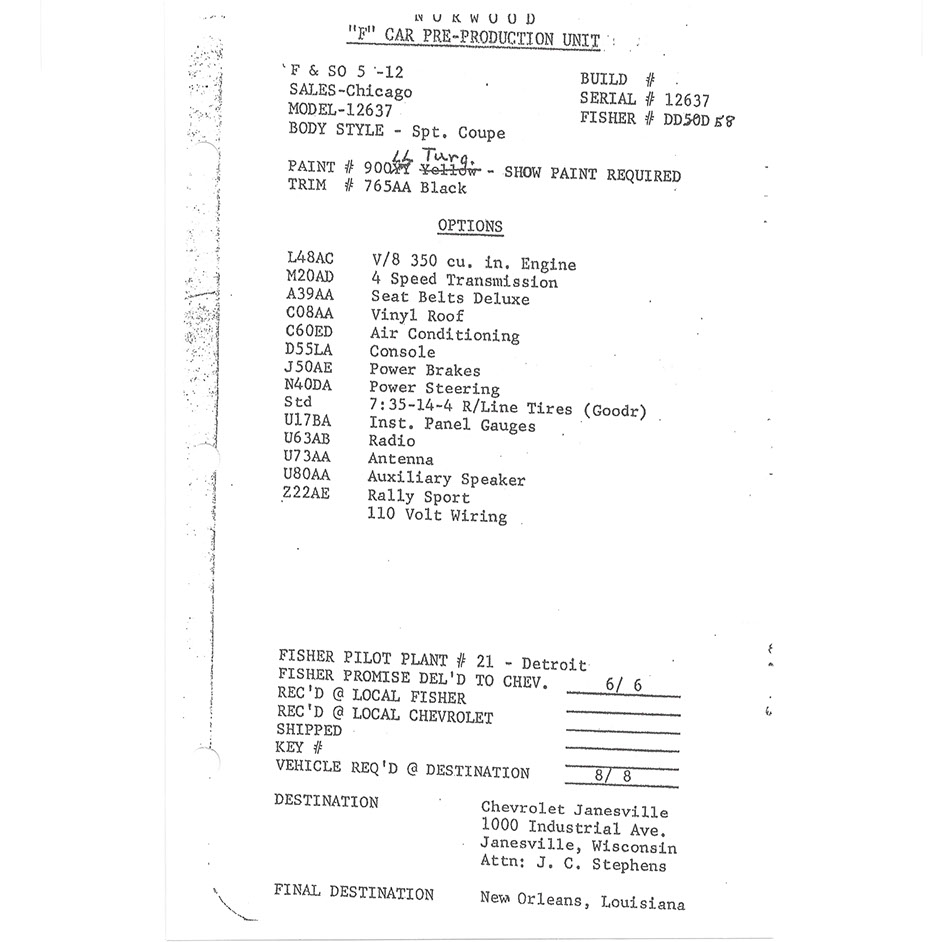

67 Original Pilot Book

Click The Image To Read

All of the Vehicles produced by the former General Motors Corporation at its long expunged Norwood, Ohio factory are all existing trademarks of the new General Motors Company. Any and all historical marks as used here are used for identification, description, illustrative, and educational purposes only. This site is not affiliated with General Motors Company.

By: Logan Lawson

Registrar Of WWW.PilotCarRegistry.com

Copyright 2014 Logan Lawson. All Rights Reserved.